No products in the cart.

Lean Manufacturing Roadmap : Your Guide to Start the Transformation Journey

Reading Time: 10 mins read

0

743

SHARES3.5k

VIEWS

Introduction: Why You Need a Roadmap Before Starting Lean

If you’ve been working in manufacturing, you’ve probably heard the buzz about “Lean Manufacturing.” It’s not just a trend — it’s a philosophy that helps companies reduce waste, improve efficiency, and deliver more value to customers.

But here’s the challenge: many factories jump into Lean too quickly. They start with tools like 5S or Kanban without building a clear plan or understanding the bigger picture. That’s where a Lean Transformation Roadmap becomes essential.

Think of it as your factory’s GPS — a guide that shows where you are now, where you want to go, and what steps will get you there. This roadmap helps teams stay focused, avoid frustration, and build a sustainable Lean culture that lasts.

In this article, we’ll walk through a simple five-step roadmap designed for beginners in manufacturing. Each step includes practical tips, real-life examples, and guidance to help you start your own Lean journey confidently.

Understanding Lean: It’s More Than Just Efficiency

What “Lean” Really Means

Lean Manufacturing isn’t about cutting costs or pushing people to work faster. It’s about creating more value for customers with fewer resources.

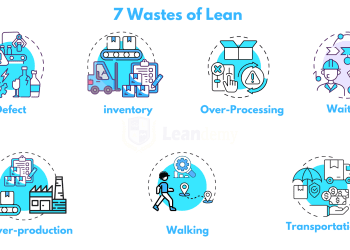

The concept started from the Toyota Production System (TPS), where the main focus was to eliminate muda — or waste — in every process. Waste can mean overproduction, waiting, unnecessary movement, excess inventory, defects, or underused talent.

When you reduce waste, your processes naturally become more efficient and your quality improves. The goal isn’t just to “do more with less” — it’s to build a smarter, more flexible production system.

Why Lean Mindset Comes Before Tools

Before you introduce any Lean tools, you need to develop the right mindset. Many companies fail in their Lean journey because they treat it as a short-term project instead of a cultural shift.

For example, a factory might implement 5S (Sort, Set, Shine, Standardize, Sustain) but stop after organizing the workplace. Without continuous discipline and leadership support, it fades away.

Lean transformation begins when everyone — from operators to managers — believes in solving problems, improving processes, and respecting people.

2️⃣ Setting the Foundation: Start Small, Think Long-Term

Assess Your Current State

Before setting any goals, take a close look at your current operations. Use tools like Value Stream Mapping (VSM) to visualize your process flow — from raw material to finished product.

In one medium-sized electronics plant, the team discovered that 30% of their total production time was spent waiting between assembly and testing. Identifying this waste allowed them to redesign the workflow and reduce lead time by 20%.

Your Lean Transformation Roadmap starts with understanding what’s really happening on the shop floor.

Build Your Lean Team

You don’t need a big department to start Lean. Begin with a small, committed cross-functional team — maybe one from production, one from quality, and one from maintenance.

Give them time and space to experiment. A small pilot team can prove early success and inspire others to join later. Lean isn’t about hiring consultants; it’s about empowering your people to find better ways of working.

3️⃣ Step-by-Step Approach: A Multi-Year Lean Transformation Roadmap

A true Lean Transformation Roadmap is not a short-term efficiency project but a multi-year journey to embed Lean principles into every layer of the organization.

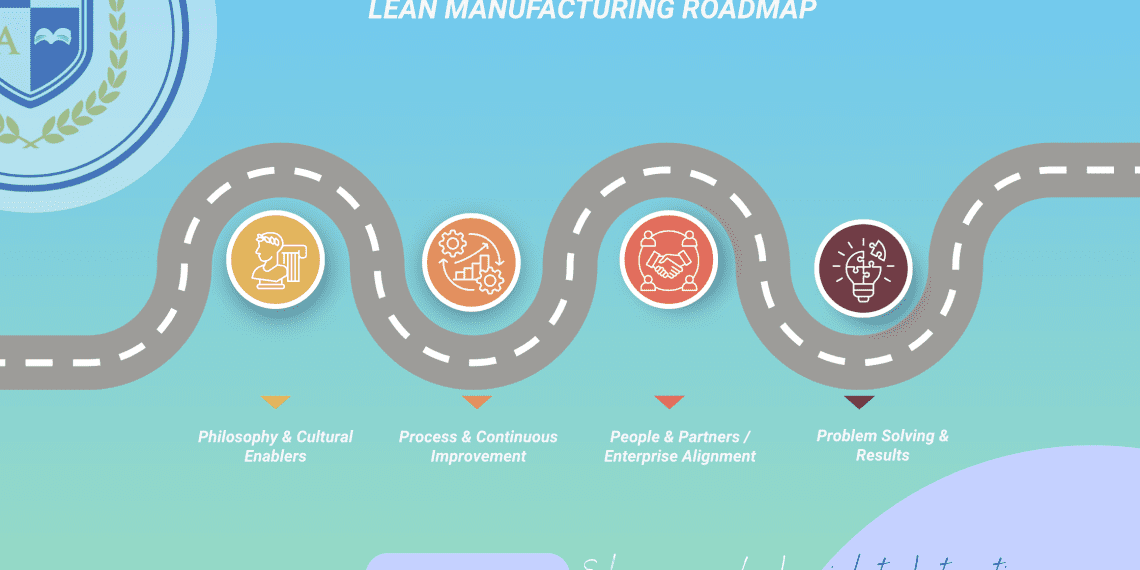

This roadmap should connect Toyota’s 4P model — Philosophy, Process, People & Partners, and Problem Solving — with Shingo’s 4 Dimensions — Cultural Enablers, Continuous Process Improvement, Enterprise Alignment, and Results.

Below is a tactical 5-year implementation framework that aligns Lean deployment with your corporate strategy, ensuring sustainability and measurable business impact.

Year 1 – Philosophy & Cultural Enablers: Define the Why and Align the Vision

Strategic Objective: Establish the organizational purpose, leadership mindset, and cultural base for Lean.

Key Actions:

- Launch Hoshin Kanri strategic planning with an X-Matrix linking vision, breakthrough objectives, and key Lean initiatives.

- Communicate the Lean philosophy company-wide — emphasizing customer value, long-term thinking, and respect for people.

- Conduct leadership alignment workshops to develop Lean leadership behaviors (Gemba walks, servant leadership, coaching).

- Assess baseline metrics: safety, quality, delivery, cost, morale (SQDCM).

- Form a Lean Steering Committee with executive sponsors for each pillar.

Deliverables:

- Lean Vision Statement & Policy Deployment Matrix

- Leadership Training Curriculum

- Baseline Lean Maturity Assessment

Strategic Link: Corporate vision → Purpose-driven culture → Strategic clarity.

Year 2 – Process & Continuous Improvement: Stabilize and Simplify Core Operations

Strategic Objective: Create process stability and eliminate waste to improve cost, quality, and delivery performance.

Key Actions:

- Conduct Value Stream Mapping (VSM) for core product families to visualize waste and flow constraints.

- Implement foundational tools: 5S, Kamishibai Board, Standardized Work, Kanban, and SMED.

- Deploy Kaizen events to target high-impact pain points (e.g., changeover reduction, layout redesign).

- Introduce Tiered Daily Management System for tracking metrics and escalating issues.

- Align improvement projects with business KPIs from the X-Matrix.

Deliverables:

- Stabilized pilot line with measurable OEE gains

- Standardized Work documents

- Visual factory dashboards

Strategic Link: Operational excellence supports strategic cost leadership and delivery reliability.

Year 3 – People & Partners / Enterprise Alignment: Empower and Expand

Strategic Objective: Build Lean capabilities across teams and extend collaboration to suppliers and partners.

Key Actions:

- Create Lean capability development roadmap (Operator → Team Leader → Lean Coach → Manager).

- Certify Six Sigma Green Belts / Lean Practitioners in improvement and problem-solving techniques.

- Align all department goals through Hoshin Kanri catchball sessions — ensuring top-down and bottom-up alignment.

- Engage suppliers in joint Kaizen and JIT / Kanban integration for value chain optimization.

- Build cross-functional improvement teams to solve systemic issues.

Deliverables:

- Annual competency matrix & training scorecard

- Supplier development scorecard

- Integrated KPI review process

Strategic Link: Human capital development + supply chain alignment drives enterprise-wide competitiveness.

Year 4 – Problem Solving & Results: Institutionalize Learning and Accountability

Strategic Objective: Establish a company-wide problem-solving culture that drives measurable performance.

Key Actions:

- Deploy A3 Problem Solving and Root Cause Analysis (RCA) for all critical issues.

- Conduct daily and weekly Gemba reviews at leadership level to support frontline teams.

- Introduce obeya rooms (visual control centers) for project tracking and KPI performance.

- Institutionalize PDCA (Plan-Do-Check-Act) and SDCA (Standardize-Do-Check-Act) cycles.

- Recognize and reward teams for continuous improvement impact.

Deliverables:

- Company-wide A3 problem library

- Gemba Walk standard checklist

- Monthly Lean results review

Strategic Link: Continuous learning and structured problem solving improve results and sustain excellence.

Year 5 – Integrated Excellence & Long-Term Sustainability

Strategic Objective: Make Lean an integrated management system that continuously drives results.

Key Actions:

- Integrate Lean metrics into corporate performance dashboards and balanced scorecards.

- Benchmark internal best practices and conduct Shingo-style self-assessments for maturity validation.

- Establish Lean Office or Center of Excellence (CoE) to govern standards and coach new sites.

- Extend Lean to new business functions — product development, HR, maintenance, and sales.

- Continue leadership development and digital transformation alignment (e.g., Lean + Industry 4.0).

Deliverables:

- Lean Management System (LMS) manual

- Annual Shingo & Toyota 4P alignment review

- Enterprise performance improvement >10% YoY

Strategic Link: Lean becomes the operating system of the business — enabling innovation, agility, and sustainable growth.

Outcome: A Strategically Aligned Lean Organization

By integrating Toyota’s 4Ps and Shingo’s 4 Dimensions, your Lean Transformation Roadmap becomes a powerful, strategy-driven journey.

It ensures that every improvement — from leadership behavior to shop-floor process — directly supports the company’s long-term vision, creating a culture of continuous learning, performance, and respect for people.

Use the Inverse of PDCA Cycle to Review The progress ( CAPD )

PDCA — Plan, Do, Check, Act — is the heart of Lean thinking. Every improvement project should follow this loop:

- Plan the change.

- Do implement it on a small scale.

- Check results using data.

- Act to standardize or adjust.

Example:

A packaging line tested a new layout under the PDCA cycle. After two weeks, data showed a 15% increase in efficiency, so the layout was standardized and scaled to other lines.

These small, disciplined learning loops create continuous strategic alignment and build momentum for long-term transformation.

Governance Tip:

Every Hoshin goal or Lean project should have a PDCA tracker visible on management dashboards, ensuring transparency from strategy to execution.

4️⃣ Building Lean Culture: The Human Side of Transformation

Empower People at Every Level

Lean transformation fails when it becomes a top-down initiative. Success happens when every employee feels ownership.

At one automotive supplier, operators were trained to identify daily problems and run mini Kaizen events. Over time, their suggestions reduced defect rates by 25%. When people feel trusted, they become the driving force of continuous improvement.

Encourage everyone to ask: “How can we make this process better today?”

The Change agents

As one of success and strategic involvmeent of lean transformation were to had change agents within the function to drive acceeration of lean mindset and practice. The cahnge agents were can be anyone not necesarily in mangerial level but he is the mentor and advocate within smaller functional team to implement lean roadmap

the cahnge agent were coached and handpicked by lean transformation program manager. With periodical review upon the obstacle and implementation of Kaizen event to solve issue witin the functions

this sesion often called kata coaching sessions that aligned the team skill set and capability into organization strategic goals

Celebrate Small Wins

Change takes time. Recognizing small achievements builds momentum. Whether it’s reducing setup time by 5 minutes or improving 5S compliance, celebrate progress publicly.

Simple actions — like displaying a “Lean Champion of the Month” board — can motivate others and keep the energy alive.

5️⃣ Sustaining Momentum: Keep Lean Alive

Standardize and Share Learnings

Sustainability starts with standardization. Document new processes, create visual work instructions, and train new employees consistently.

One food manufacturing company developed a “Lean Playbook” — a simple digital document with all their successful practices, photos, and results. It became a living reference for future improvements.

When teams share what works, Lean stops being a project and becomes part of daily operations.

Leveraging Leader habit

In today’s fast-paced and competitive business environment, organizations are continually seeking ways to enhance efficiency, foster innovation, and maintain a culture of continuous improvement. Read blog post below to better understand pivotal concept on how to lead operation with sustainability

when we think about a leader we often think about sharp mind, Quick instincts and Solid judgement. They are able to conduct holistic risk assessment and quick and concise decision making.

However, study shows how human brain process information and access current condition are wired with condition called biases and unconditional biases are something that so sublime which we do not feel and seep into pur decision making process.

there are one tools called Leader standard work

Leader standard work is a set of tools in form of checklist to assure cadence and routines which are important to operations or process being executed.

LSW encourages leaders to be actively involved in daily processes, promoting a culture of accountability and continuous improvement. Key components of LSW include:

- Gemba Walks: Regular visits to the workplace to observe processes and engage with employees.

- Standardized Meetings: Scheduled discussions focusing on performance metrics and problem-solving.

- Visual Management Tools: Use of dashboards and boards to track progress and identify issues.

- Coaching and Feedback: Ongoing support and development for team members.

By adhering to these practices, leaders can identify inefficiencies, support their teams effectively, and drive sustainable improvements.

Leverage Digital Tools

Modern Lean doesn’t mean ignoring technology. Digital dashboards, sensors, and AI-driven analytics can help track performance in real time.

For example, using a simple OEE dashboard, one factory identified machine downtime patterns and implemented predictive maintenance, reducing unplanned stops by 40%.

Technology is a powerful enabler — but only when combined with the Lean mindset.

Lean Manufacturing Roadmap for Beginners Conclusion: Your Journey Starts Today

Lean transformation isn’t a one-time project — it’s a continuous journey. The goal of the Lean Transformation Roadmap is not perfection, but steady progress toward excellence.

Start small. Focus on one process, involve your people, and keep learning. Every improvement — no matter how minor — brings your factory closer to becoming truly Lean.

Remember: Lean is not about tools, it’s about people and mindset.

Once that culture takes root, everything else — efficiency, quality, and customer satisfaction — naturally follows.

Bonus Insight: Why Lean Manufacturing Still Matters Today

According to a recent article on Leandemy.com, Lean Manufacturing continues to be one of the most relevant strategies for industrial success. The philosophy centers on “creating more value with less waste,” helping companies stay competitive without relying on higher prices or larger production capacity. From its origins in the 18th century and the Toyota Production System of the 1950s to the modern digital factory, Lean has evolved — but its essence remains the same: continuous improvement and respect for people.

Leandemy highlights five reasons Lean manufacturing still thrives today:

- It evolves with changing industry needs.

- It drives profitability and sustainability by cutting waste.

- It applies across industries, not just manufacturing.

- It’s cost-effective and accessible for small to mid-sized firms.

- It builds a culture of teamwork and shared ownership.

Case Study Example:

A small automotive parts manufacturer once struggled with long changeover times and rising defect rates. Instead of investing in automation, they followed a simple Lean Transformation Roadmap — starting with 5S for workplace organization, SMED to shorten setup times, and daily Kaizen meetings. Within six months, changeovers dropped by 35%, defects by 20%, and operator engagement rose dramatically. The result wasn’t just better performance — it was a cultural shift toward problem-solving and accountability.

This case proves that Lean is not a toolset, but a mindset — one that remains vital for manufacturers striving to stay competitive, resilient, and people-focused in the modern industrial world.

Aji

Hi there welcome to leandemy.com, with decade of experience in lean and manufacturing I'd love to share ideas and know how to better understand of lean practice

Related Posts

A3 Problem Solving Ultimate Guide : Decoding Rootcause with 7 step 7 tools

A3 problem-solving Templates are one of lean manufacturing tools. It has practical ways to un woven complex issues. In the complex world of business operations, problems are inevitable. Whether they are small hiccups or significant hurdles,...

Hoshin Kanri : Translating Your Business Strategy into Roadmap

How Hoshin Kanri Can Steer Your Business Strategy Are you : Feeling lost at sea with your business goals? Staring at a strategic plan that feels disconnected from daily operations? If so, then Hoshin Kanri might...

Visual Management in the Operation : The Navigating Clarity in dynamic workplace

Visual management is the game-changer you didn't know your workplace needed! Imagine a world where everyone's on the same page, errors are minimized, and communication flows seamlessly—that's the power of visual management. In simple terms, visual...

A Comprehensive Guide to Total Productive Maintenance

In today's fast-paced industrial landscape, maximizing productivity while minimizing downtime is crucial for success. One approach gaining traction is Total Productive Maintenance (TPM), a proactive maintenance strategy aimed at optimizing equipment effectiveness. Recent studies converge...

Kaizen: The Power of Shifting Mindset & Domino effect towards efficiency

Kaizen often mentioned methodologies which leverage the bussiness. In the dynamic landscape of manufacturing, businesses are constantly seeking ways to enhance efficiency, productivity, and overall performance. One approach that has gained significant traction in recent years...

The 7 Waste of Lean : Magnifying Loss & Navigating Strategies

Ever feel like your business is bogged down, struggling to meet deadlines and stay competitive? You're not alone. Hidden within your processes lie silent killers known as the "7 Wastes of Lean." These efficiency vampires suck...

Please login to join discussion

ADVERTISEMENT