No products in the cart.

Just-In-Time introduction : A Catalyst for Lean Production Excellence

Reading Time: 12 mins read

0

774

SHARES3.7k

VIEWSJust-In-Time, often abbreviated as JIT, is a lean manufacturing principle rooted in the idea of producing only what is needed, precisely when it is needed. The core tenet of JIT lies in the elimination of waste at every stage of the production process. By strategically aligning production with demand, JIT ensures that resources are utilized efficiently, reducing excess inventory and associated costs.

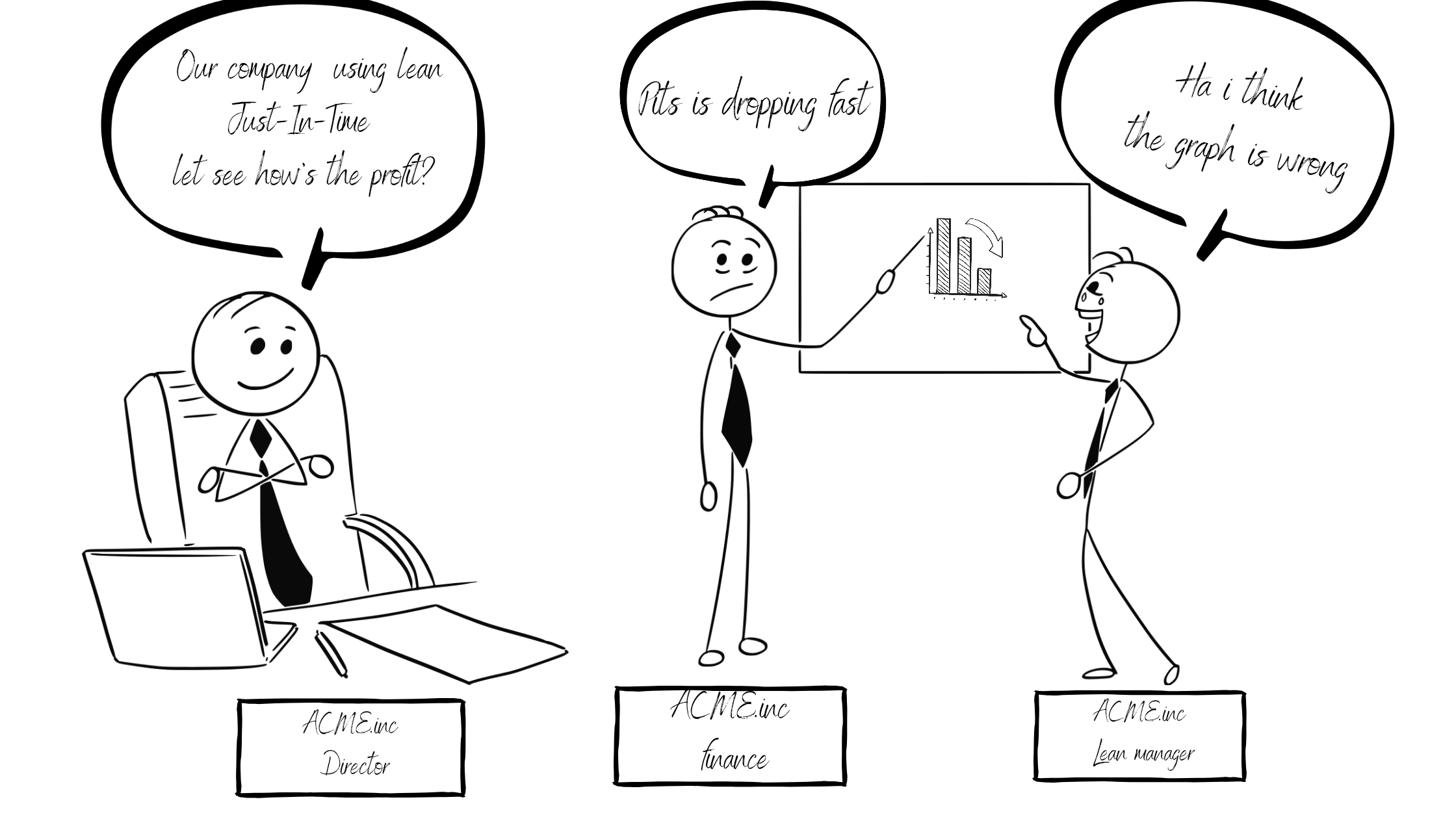

With recent Covid 19 case, globally all firm understand the importance of JIT. Thexresearch shown that companies implementing lean Just-In-Time inventory management had more profit than who doesn’t

In the ever-evolving landscape of manufacturing, efficiency is the linchpin that holds the entire process together. One methodology that has garnered significant attention in recent years is Just-In-Time (JIT), a fundamental principle of Lean production. In this blog post, we delve into the core pillars of JIT, unraveling its essence and its profound impact on eliminating waste and maximizing efficiency in the manufacturing realm.

How Does Just-in-Time Inventory Management Work?

Efficiency in manufacturing hinges on the strategic orchestration of resources, and Just-In-Time (JIT) inventory management stands at the forefront of this operational finesse. To understand how JIT works, we must delve into its fundamental steps, technological prerequisites, and the nuanced risks and considerations associated with its implementation.

Stages of Just-In-Time Implementation: Crafting Efficiency Through Precision

At its core, JIT inventory management revolves around producing goods precisely, When they are needed and in the quantities required. The first step involves closely monitoring customer demand, enabling manufacturers to align production schedules with actual market needs. This demand-driven approach minimizes the risk of overproduction and excess inventory, fostering a lean and agile manufacturing process.

Step 1: Design Just-In-Time Priorities as a Pilot

Initiate the JIT journey by carefully designing priorities, focusing on materials, product types, and other critical elements. Implementing a pilot project allows for a controlled introduction of JIT principles, assessing their feasibility and impact on a smaller scale before full-scale integration.

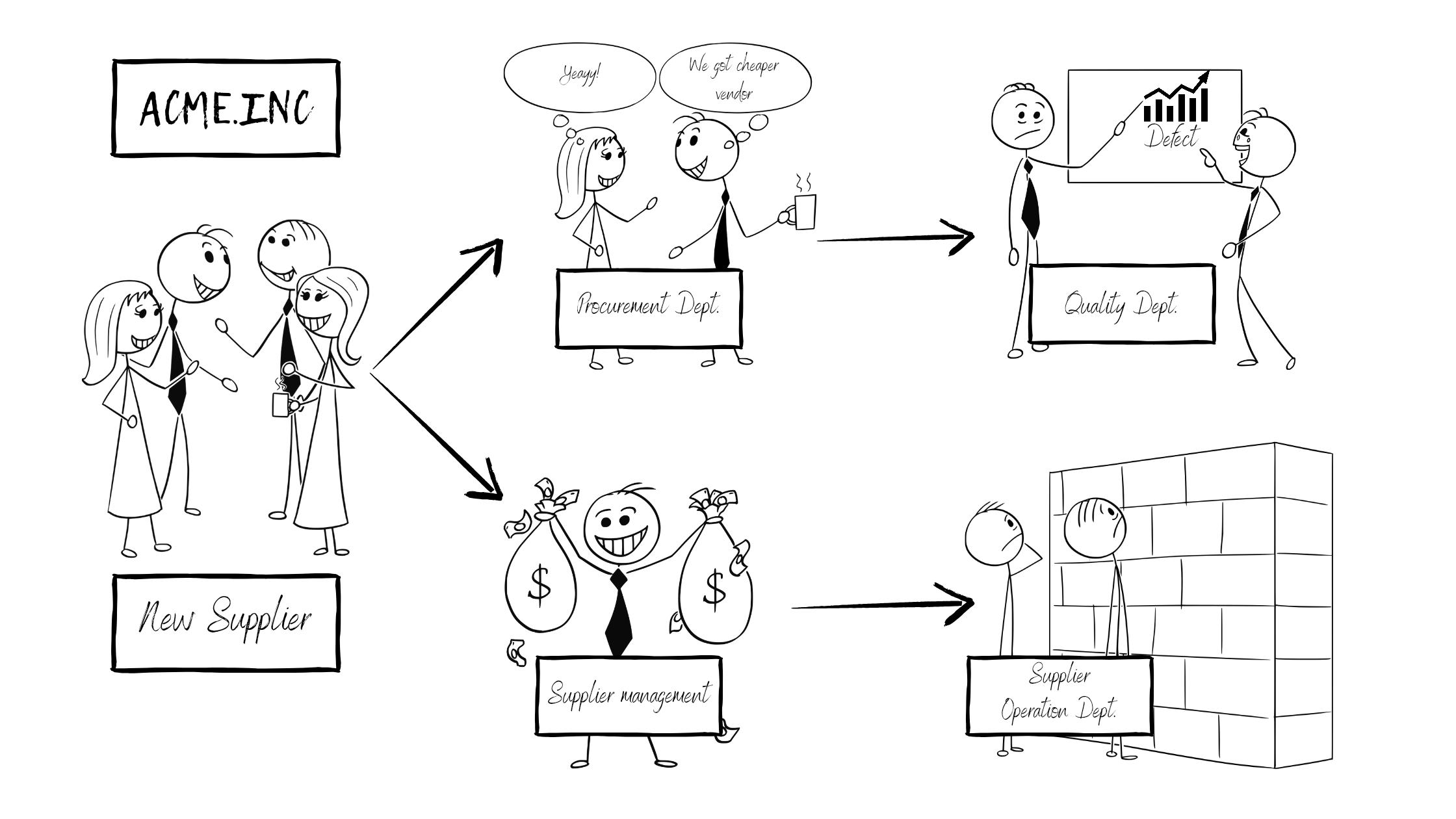

Step 2: Develop Suppliers with Quality Management Focus

Build a robust supplier network by selecting partners based on stringent quality management criteria measured through quality-of-service metrics. Quality assurance at the supplier level is pivotal to ensure a seamless and reliable flow of materials, aligning with JIT’s demand-driven philosophy.

Step 3: Define Customer Takt and Implement Heijunka

Define customer takt time, the maximum allowable time to produce a product to meet customer demand. Implement Heijunka, or level scheduling, to align production with this defined rhythm, smoothing out variations and optimizing the production process for efficiency.

Step 4: Pull System Implementations in Production

Introduce pull systems within the production process, shifting from traditional push-based methods to a demand-driven approach. By initiating production based on actual customer demand, pull systems minimize lead times and enhance overall responsiveness.

Step 5: Review Work-in-Progress Inventory Level Bottlenecks

Conduct a thorough review of work-in-progress inventory levels, identifying potential bottlenecks through metrics such as days of inventory. This stage emphasizes the critical importance of streamlining inventory to eliminate excess and ensure a continuous flow.

Step 6: Define Kaizen in Bottleneck Stages

Implement Kaizen principles specifically targeted at bottleneck stages. Continuous improvement is key to addressing inefficiencies identified in the production process, ensuring a constant cycle of refinement and optimization.

Step 7: Horizontal Deployment to Other Product Processes

Extend the JIT philosophy horizontally to other product processes and opportunities within the organization. Horizontal deployment ensures that the efficiency gains achieved in one area are replicated across the broader spectrum, creating a culture of continuous improvement throughout the entire production landscape.

In navigating these seven stages of JIT implementation, manufacturers pave the way for a transformative shift towards efficiency, waste reduction, and responsiveness in the dynamic realm of modern production.

Pros and Cons of Just-In-Time

Just-In-Time, like any operational methodology, comes with its set of advantages and challenges. Let’s explore ten key pros and cons, shedding light on their impact on businesses:

Pros:

1. Cost Reduction: JIT minimizes carrying costs, reducing the financial burden associated with excess inventory.

2. Improved Efficiency: Streamlined production processes lead to increased efficiency and resource optimization.

3. Waste Reduction: JIT eliminates waste by producing only what is needed, contributing to environmental sustainability.

4. Quick Response to Market Changes: JIT allows for rapid adaptation to shifts in customer preferences and market dynamics.

5. Enhanced Product Quality: Tight control over production processes and materials ensures a higher level of product quality.

Cons:

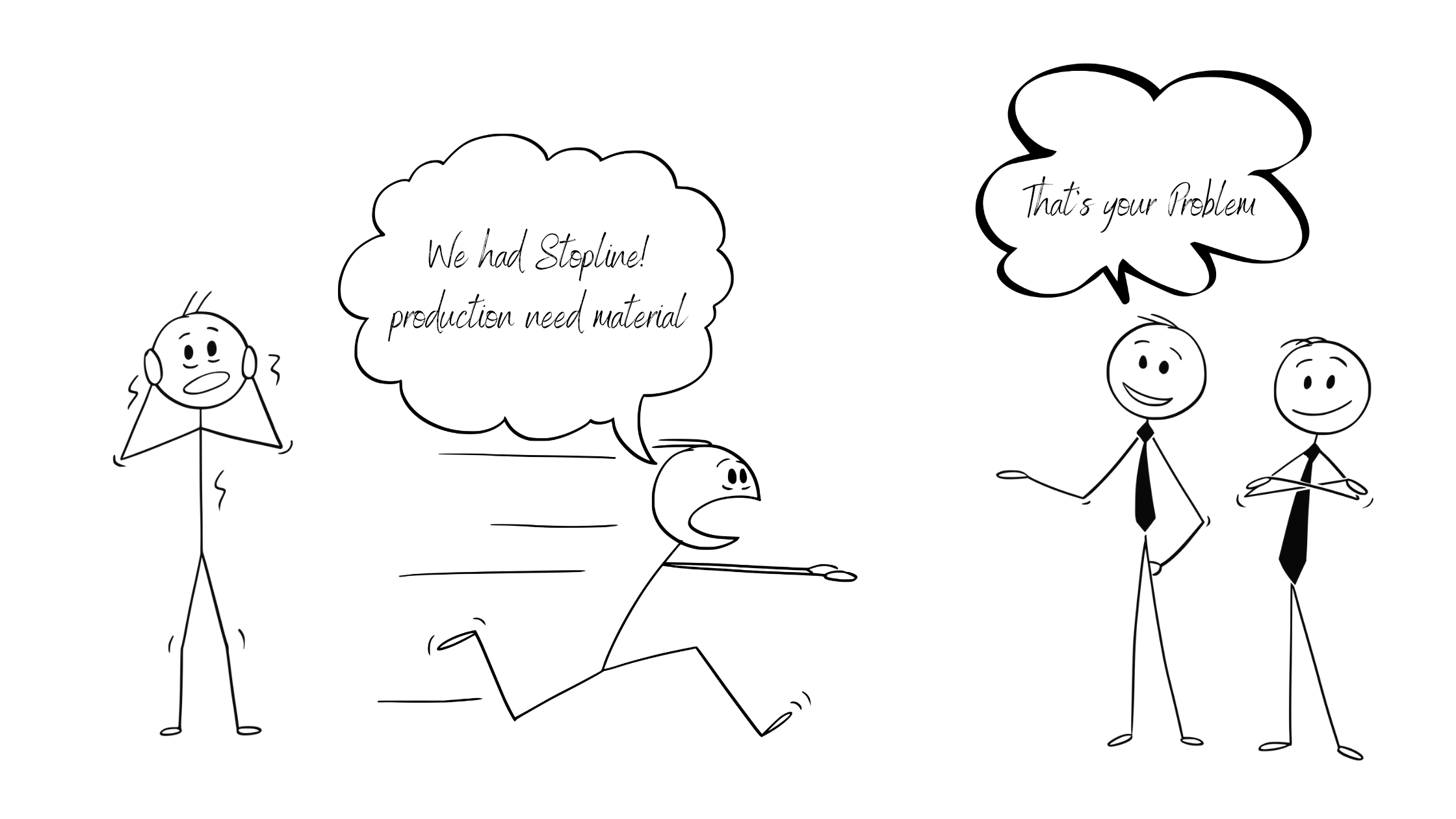

1. Supply Chain Vulnerability:Dependence on a single-source supplier increases susceptibility to disruptions.

2. Rigidity in Production: JIT may struggle to adapt to sudden spikes in demand, leading to production bottlenecks.

3. Technology Dependence: Implementation requires advanced technology, potentially excluding smaller businesses.

4. Costly Set-Up: Establishing JIT systems incurs initial costs for technology, training, and process reengineering.

5. Demand Forecasting Challenges: Inaccurate demand forecasting can lead to underproduction or overproduction.

What Companies Implement Just-In-Time?

The adoption of Just-In-Time inventory management has become a hallmark of efficiency for many globally recognized companies. Let’s examine examples from twelve Fortune 500 companies, shedding light on the impact of JIT on their operational excellence.

1. Toyota: Pioneering JIT, Toyota revolutionized manufacturing, achieving a lean and responsive production system.

2. Apple: Embracing JIT principles in its supply chain, Apple minimizes inventory holding costs and swiftly adapts to changing consumer demands.

3. Walmart: The retail giant leverages JIT to optimize its inventory levels, ensuring products are on the shelves precisely when needed.

4. Dell: JIT allows Dell to maintain a lean inventory of customizable components, fulfilling customer orders promptly.

5. Honda: Following Toyota’s lead, Honda implements JIT to streamline production and reduce waste in its manufacturing processes.

6. Boeing: The aerospace giant employs JIT to enhance efficiency in its complex supply chain, ensuring timely production of aircraft components.

7. Procter & Gamble: JIT aids P&G in managing its vast array of products, minimizing excess inventory and improving supply chain responsiveness.

8. Intel: JIT principles are applied in Intel’s manufacturing processes, facilitating the production of semiconductors with minimal lead times.

9.Ford: Ford has embraced JIT to optimize its production lines, reducing inventory costs and improving overall operational efficiency.

10. Nissan: Implementing JIT has allowed Nissan to streamline its production processes, reducing waste and enhancing flexibility.

11. General Electric: GE utilizes JIT to optimize its manufacturing operations, ensuring the timely production of critical components.

12. Sony: JIT is integral to Sony’s manufacturing strategy, enabling the company to respond swiftly to shifts in consumer demand for electronic products.

In conclusion, Just-In-Time inventory management transcends industries, offering a blueprint for enhanced efficiency and responsiveness. As these exemplary Fortune 500 companies showcase, embracing JIT principles is not merely a strategic choice but a transformative approach to thrive in the dynamic landscape of modern industry.

Types of Just-In-Time : A Symbiotic Relationship Lean Production framework

JIT is intricately woven into the fabric of Lean production, a holistic approach that seeks to optimize efficiency across the entire value chain. At its core, Lean is about creating more value for the customer with fewer resources, and JIT plays a pivotal role in achieving this objective. The synergy between JIT and Lean lies in their shared commitment to eliminating waste, enhancing quality, and fostering continuous improvement.

Just-in-Time Delivery (JITD): Precision in Material Supply

Just-In-Time Delivery (JITD) emerges as a critical component in the intricate dance of Lean manufacturing. This specific application focuses on the timely delivery of materials to production exactly when needed, seamlessly dovetailing with the principles of JIT manufacturing. JITD is the linchpin that ensures a continuous and efficient flow of materials, optimizing the production process to the utmost degree.

Specific Application: JITD in Conjunction with JIT Manufacturing

JITD operates hand-in-hand with JIT manufacturing, creating a harmonious synergy that maximizes efficiency. This specific application involves delivering materials precisely when they are needed, aligning with the demand-driven philosophy of JIT. By synchronizing the delivery of raw materials with the production schedule, JITD minimizes the need for extensive warehousing, reduces carrying costs, and ensures that resources are utilized judiciously.

Aiming for Precision: Delivering Materials Right Before They are Needed

At the core of JITD is the strategic aim of delivering materials right before they are needed in the production process. This precision-oriented approach minimizes lead times, reduces excess inventory, and fosters a dynamic production environment. The goal is to optimize the supply chain, ensuring that materials arrive at the production line precisely when they are required, eliminating unnecessary waiting times and enhancing overall efficiency.

Just-in-Time Scheduling: Dynamic Precision in Production Planning

Just-In-Time Scheduling (JITS) stands as a testament to the dynamic nature of Lean manufacturing, aiming to revolutionize the traditional approach to production planning. This scheduling methodology is intricately woven into the fabric of JIT, with a primary objective of minimizing lead times and aligning production schedules with actual demand fluctuations.

Scheduling Approach: Minimizing Lead Times and Aligning with Demand

JIT scheduling operates on the principle of dynamic precision, seeking to minimize lead times and enhance overall production efficiency. Traditional manufacturing schedules often rely on fixed intervals and forecasted estimates, leading to inefficiencies and excess inventory. JITS, on the other hand, embraces a dynamic scheduling approach based on real-time needs. By closely monitoring customer demand and adjusting production schedules accordingly, manufacturers can respond promptly to market fluctuations, reduce waiting times, and ensure a seamless flow of production.

Aiming for Dynamism: Real-time Scheduling to Meet Market Needs

The overarching aim of JIT scheduling is to introduce dynamism into the production planning process. By dynamically scheduling production based on real-time needs, manufacturers can adapt swiftly to changes in customer preferences and market dynamics. This not only minimizes the risk of overproduction but also positions the manufacturing process to be agile and responsive, ensuring a competitive edge in the fast-paced landscape of modern industry.

How Just-In-Time reduce costs: Unveiling the 60% Manufacturing Cost Revelation

A staggering revelation underlines the significance of JIT in manufacturing – approximately 60% of the costs are tied up in raw materials, primarily existing as inventory. This statistic underscores the financial implications of excess inventory and the substantial impact JIT can have on reducing these costs. By aligning production with demand, JIT minimizes the need for extensive warehousing and storage, liberating capital and optimizing resource allocation.

Eliminating Waste: The Essence of JIT

At the heart of JIT lies the relentless pursuit of waste elimination. Traditional manufacturing often results in overproduction, excess inventory, and unnecessary waiting times – all of which contribute to increased costs. JIT, on the other hand, streamlines the production process, producing goods only as they are needed in the subsequent stage of the manufacturing chain.

Core Benefits of JIT: Navigating the Lean principles into action

1. Demand-Driven Production

JIT operates on the premise that production should be demand-driven. By closely monitoring customer demand and adjusting production schedules accordingly, manufacturers can avoid the pitfalls of overproduction and excess inventory. This pillar emphasizes the importance of staying attuned to market dynamics and adjusting production levels in real-time.

2. Takt Time and Continuous Flow

Takt time, a key concept in JIT, defines the maximum time allowed to produce a product in order to meet customer demand. Aligning production cycles with takt time ensures a continuous flow of products, minimizing bottlenecks and optimizing efficiency. This pillar emphasizes the synchronization of production processes to maintain a seamless flow from raw materials to finished goods.

3. Pull System: A Paradigm Shift

Central to JIT is the adoption of a pull system, where production is initiated based on actual customer demand rather than forecasted estimates. This paradigm shift eliminates the need for excessive stockpiles and promotes a more responsive and agile manufacturing process. By pulling resources into production only when needed, manufacturers reduce lead times and enhance overall flexibility.

4. Flexibility and Adaptability

The ability to adapt swiftly to changing market demands is a cornerstone of JIT. Flexibility in production processes allows manufacturers to respond promptly to shifts in customer preferences or unforeseen disruptions. This pillar underscores the importance of fostering a culture of continuous improvement and adaptability to thrive in dynamic market conditions.

Barrier to implement Just-In-Time methodologies

Embarking on the journey to implement Just-In-Time (JIT) methodologies signifies a commitment to efficiency, waste reduction, and a transformative shift in operational practices. While the rewards are substantial, the path to JIT implementation is not without its challenges. In this exploration, we unravel the intricacies surrounding the barriers that organizations may encounter as they strive to adopt JIT principles.

The road to JIT excellence is paved with technological prerequisites, quality management considerations, and the need for a cultural transformation that engages every level of the organization. As we navigate through these barriers, we shed light on the strategies and insights that can guide companies towards overcoming challenges and unlocking the full potential of JIT methodologies

Below are some barriers to implement Just-In-Time methodologies:

1.Technology Prerequisites to JIT Implementation

The successful implementation of JIT relies on a technological infrastructure that facilitates real-time communication and data exchange. Advanced Enterprise Resource Planning (ERP) systems, sophisticated demand forecasting tools, and seamless connectivity across the supply chain are prerequisites for JIT efficiency. These technologies empower manufacturers to make informed decisions based on real-time data, ensuring precision in production planning and material supply.

2. Risks of Single Source Supplier and the Role of Quality Management

While JIT brings unparalleled efficiency, reliance on a single-source supplier poses a potential risk. Supply chain disruptions, unforeseen market changes, or supplier-related issues could jeopardize the continuous flow of materials. Quality management becomes paramount in mitigating these risks. Rigorous quality control measures and strategic supplier partnerships are essential to maintain the reliability of the supply chain and uphold product standards.

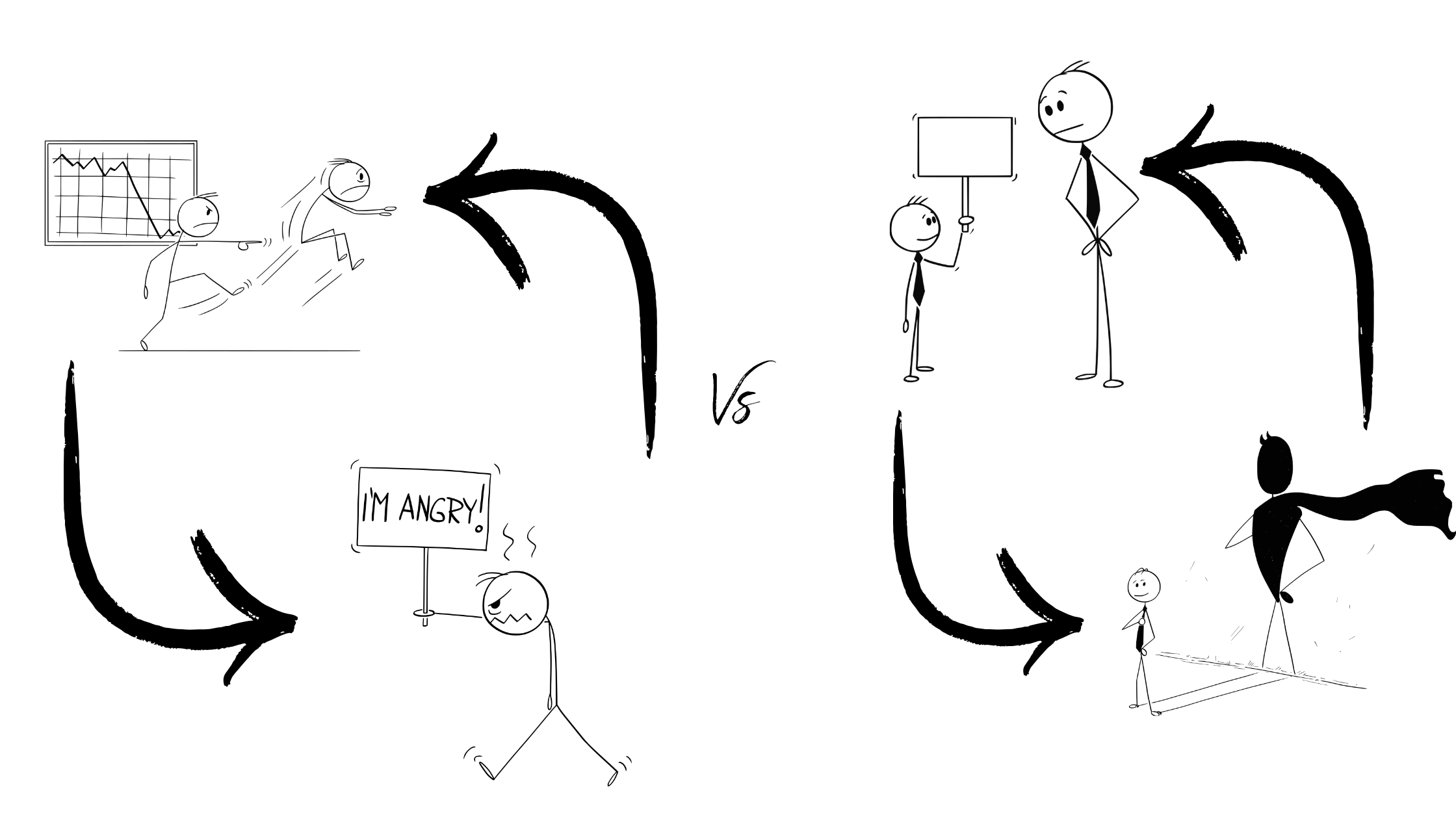

3. Cultural Transformation vs Cost Reductions: How Companies Engage All Levels to Implement JIT

Implementing Just-In-Time (JIT) methodologies goes beyond technological upgrades; it necessitates a profound cultural transformation within an organization. Companies committed to JIT engage employees at all levels, fostering a culture of continuous improvement. This cultural shift involves empowering employees to identify inefficiencies, contribute to decision-making, and actively participate in the lean production journey.

Companies that successfully implement JIT prioritize employee involvement. Cross-functional teams collaborate to identify waste, improve processes, and embrace the principles of lean manufacturing. This cultural transformation not only enhances efficiency but also instills a sense of ownership and accountability among employees, aligning everyone towards the common goal of operational excellence.

4. Financial Metrics: How Companies Track Cost Reductions in JIT Implementation

Tracking the impact of Just-In-Time (JIT) implementation on cost reduction requires a meticulous focus on financial metrics. Companies adopting JIT employ key performance indicators (KPIs) to measure the tangible benefits of lean production.

One crucial financial metric is the reduction in carrying costs. By minimizing excess inventory, companies free up capital, reduce storage expenses, and improve overall cash flow. Additionally, JIT’s impact on lead times and production efficiency directly influences metrics such as Return on Assets (ROA) and Return on Investment (ROI).

Companies leverage metrics like Inventory Turnover Ratio and Days of Inventory to assess the effectiveness of JIT in streamlining supply chains and optimizing inventory levels. Reduced lead times contribute to faster cash conversion cycles, positively impacting financial health.

Moreover, the focus on quality management, another integral aspect of JIT, reflects in metrics such as Cost of Poor Quality (COPQ). By emphasizing prevention over inspection, companies can reduce costs associated with defects and rework.

5. Communication and Delegation of Authority: Essential Elements for JIT Implementation

Implementing Just-In-Time (JIT) methodologies demands effective communication and streamlined delegation of authority. Fast decision-making is crucial when unforeseen events occur or outliers challenge the system. JIT relies on prompt approval and countermeasure implementation to maintain the flow of operations.

Clear communication channels are essential for disseminating information rapidly across departments. This ensures that everyone is aligned with the lean production principles and can act swiftly when necessary. Regular communication and feedback loops help in identifying bottlenecks and implementing improvements proactively.

Delegation of authority within the organization facilitates empowered decision-making at various levels. Teams must be empowered to make decisions on the shop floor without unnecessary bureaucracy, enabling a more agile response to challenges. This decentralized decision-making approach aligns with the JIT philosophy of continuous improvement and adaptability in the face of changing circumstances.

Conclusion:

In conclusion, Just-In-Time stands as a beacon of efficiency in the realm of Lean production. By meticulously aligning production with demand and focusing on waste elimination, JIT paves the way for a more streamlined, cost-effective, and responsive manufacturing process. As the manufacturing landscape continues to evolve, embracing the core pillars of JIT becomes not just a strategic choice but a necessity for those seeking to thrive in the competitive global market.

Companies Implementing JIT:

- Toyota

- Apple

- Walmart

- Dell

- Honda

- Boeing

- P&G

- Intel

- Ford

- Nissan

- GE

- Sony showcase JIT’s adaptability across diverse industries.

The journey through the intricacies of Just-In-Time (JIT) methodologies unveils a transformative approach to manufacturing that goes beyond mere efficiency. JIT stands as a beacon of lean production, emphasizing the core tenet of producing precisely what is needed, when it is needed. As we navigated through the pillars of JIT, explored its specific applications like JITD and JITS, and analyzed its impact on manufacturing costs and waste reduction, it became evident that JIT is not just a methodology; it’s a symbiotic relationship with Lean production, aiming for a seamless, demand-driven, and waste-free production environment.

Stages of JIT Implementation

- Design priorities as a pilot.

- Develop suppliers with quality focus.

- Define customer takt and implement Heijunka.

- Introduce pull systems in production.

- Review work-in-progress inventory bottlenecks.

- Define Kaizen in bottleneck stages.

- Horizontal deployment to other processes.

Understanding the stages of JIT implementation highlighted the precision required to orchestrate this lean transformation successfully. From designing priorities as a pilot to horizontally deploying JIT principles across various product processes, each step contributes to crafting efficiency through meticulous planning and continuous improvement. The emphasis on cultural transformation, technological prerequisites, quality management, and effective communication underscored the holistic nature of JIT implementation.

Pro cons Just-In-Time

As we weighed the pros and cons of JIT, it became apparent that the benefits, such as cost reduction, improved efficiency, and waste elimination, significantly outweigh the challenges. Companies like Toyota, Apple, and Walmart exemplify the success stories of JIT implementation, showcasing its adaptability across diverse industries and the positive impact on operational excellence.

Barrier of implementation

- Technology prerequisites: Advanced ERP systems, demand forecasting tools.

- Supply chain risks: Single-source supplier reliance and quality management.

- Cultural transformation: Engaging all levels for a lean culture.

- Financial metrics: Tracking cost reductions for sustainable financial health.

Delving into the barriers to JIT implementation brought attention to technological prerequisites, supply chain risks, the necessity for cultural transformation, and the role of financial metrics. Overcoming these barriers requires a strategic and comprehensive approach, where companies engage at all levels, leverage advanced technologies, prioritize quality management, and foster a culture of continuous improvement.

The financial metrics associated with JIT, from reduced carrying costs to improved return on investment, further solidified the business case for embracing JIT principles. By tracking and optimizing financial indicators, companies can not only enhance operational efficiency but also achieve sustainable financial health.

In essence, Just-In-Time is not just a set of principles; it’s a dynamic and holistic framework that adapts to the evolving landscape of manufacturing. It demands a cultural shift, technological integration, and a relentless pursuit of waste elimination. As organizations strive to implement JIT methodologies, they are not merely adopting a production philosophy; they are embracing a transformative journey towards operational excellence in the competitive and dynamic world of modern industry.

Aji

Hi there welcome to leandemy.com, with decade of experience in lean and manufacturing I'd love to share ideas and know how to better understand of lean practice

Related Posts

Scientific Thinking: Navigating between fact in statistics and human psychological bias

Understanding How the Human Brain Shapes — and Sometimes Sabotages — Operational Problem Solving If you’ve worked in manufacturing long enough, you’ve probably faced it: the same downtime keeps reappearing, the same quality defect creeps back,...

Eight Disciplines Problem Solving : Navigating Bias trough structured framework

When the Brain Becomes the Hidden Defect and decline Company sales revenue There a lot of cases where in B2B business poor customer experience and Quality issue cause the sales decline. in a survey of 1,350...

Lean Manufacturing Roadmap : Your Guide to Start the Transformation Journey

Introduction: Why You Need a Roadmap Before Starting Lean If you’ve been working in manufacturing, you’ve probably heard the buzz about “Lean Manufacturing.” It’s not just a trend — it’s a philosophy that helps...

Six Sigma vs AI: Future Talent Outlook in Continuous Improvement

Are You Lean practicioner within manufacturing industry? if yes you will notice that In all manufacturing sector the outlook of AI implemntation were growing According Research by Fortune bussiness insight , The global “AI in manufacturing”...

How to Make Hoshin Kanri X Matrix (Step-by-Step Guide)

How to Make Hoshin Kanri X Matrix (Step-by-Step Guide) Is your team great at hitting targets -- Just not the right one? Do your KPI's Change more often than your Machine changeovers? Ever feel like the...

Leader Standard Work Benefit: How to lead without falling for your own biases

Leader standard work benefit for manager is exercised to reduce your biases during decision making you will ask me how? when we think about a leader we often think about sharp mind, Quick instincts and Solid...

Please login to join discussion

ADVERTISEMENT