No products in the cart.

Lean Manufacturing Principle : Decoding Leadership Missconceptions

Misconception which leads failure in lean implementation in manufacturing industry

Reading Time: 7 mins read

0

745

SHARES3.5k

VIEWSLean manufacturing principle is a topic which increased researcher attention along the year. Based on what we found at Academia.edu the word “lean manufacturing principles” there are 313.799 Papers with increased growth year by year.

Now if you are interests in lean glorious successes, you neeed to now there are quite common missconceptions regarding lean principles. You need to be aware of key lean manufacturing principle, and it’s missconceptions during implementations. According our search lean principle ebook are quite a lot in amazon.com more than 500 ebook present

After working as lean facilitators in decade we synthesize those things in this article. This article will help you to see the lean manufacturing Principle Ideally and the missconceptions during lean framework implementations

5 Lean manufacturing principle

Lean manufacturing principle are:

- Identify the value based on customer Perspective

- Map the value from bussines to operation stream.

- Align the flow by reducing wastes .

- Implementing pull system

- Continuous Improvement

When we discuss about lean principle It always ties with lean history . Especially, with Toyota production system and it success bring value for the company. However, little were known that Toyota along the journey shared their practice and refined it to the suppliers and the sister company like the case how Single minute exchange dies being created. Shigeo Shingo during 1980’s where he saw that the similar plant produces same engine had which both using TPS however over the 5 years the performance of both plant were differ.

So based on the fact lean are much more growing when it started to expose & implement to outside Toyota. It is fair to say that lean manufacturing principle is based on hands on practice. And the practice of implementations helps organization to refine and align the ideas and principle with the business process.

And those practice can keep the lean in the same light, under the ideal lean manufacturing principle which is:

- Identify the value based on customer Perspective

- Map the value from bussines to operation stream.

- Align the flow by reducing wastes .

- Implementing pull system

- Continuous Improvement

At least those four principles were the one I feel and done during work in automotive industries in my early career. I’m really thankful to have the experience and opportunities learning lean and develop an Value stream map project. But somehow when I’m move to other industries the way they see lean principle and practice, are upside down.

Lean manufacturing principle misconceptions

My experience when joining new corporations that “claimed” enable lean feels funny. Many words jargon and new KPI’s That I would never see even in automotive company. It just like you buy a favorite carbonated drink but somehow it tastes differently and fells unable to swallow it.

When Deep dive on why it happens, the synthesize of my experience concluded it may due to misconceptions of lean principles. I would try to summarize my decade experience & view and why it would been happened. as well the key aspect to change.

Lean Manufacturing Principles First misconceptions : Understanding value, as defined by the customer Management.

Based on observational research held by Elizabeth F. Turesky -Leadership and Organizational Studies,

University of Southern Maine. Her paper published in Organization Management Journal. there are several Factors affecting success of implementation in lean manufacturing principle implementation which are:

- Top management support

- Communication

- Training and Development

- Project selection

- Employee engagement

- Desire to improve.

- Managing resistance

- Project team selections

- Completing the project

- Accountability

Managment view lean as tools to help company cost structure. But if you see how Toyota developed TPS it was based on how customer should be treated. And based on customer view they projecting what does the value add, and which is nonvalue add.

Jeffrey K. Liker on his book stated that he had consulted to and taught leaders of companies all over the world who have the mistaken belief that lean transformation can be planned and controlled, just like updating your computer software. –

The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer, 2nd Edition

Defining lean system usually prompted by new leadership appointed in order to perform the organizations and fueling with new heavy Cost reduction. While forgetting the lean is long journey to develop communal knowledge in order to outperform competitor organizations.

Lean Manufacturing Principles Second misconception : Identifying the value stream or cost reductions.

Yes you read it right, on Implementing lean System most of the time top management priority concern were the cost benefit. By Pursuing Value stream the improverment ideas able to sustain much longertime. In other hand If lean Implementation Pursuing cost reduction only it will Sustain less than 3 years short-term ideas.

Then What’s made the differences between pursuing Value stream with cost reductions? The key were Sustainability.

Most of lean tranformations were not sustained more then 4 years Why?

Based on decade of Lean practice, Some points basedmy observations below :

- There are Some Clashes between lean concept and company guiding principle or core Organization key results.

- Short term project not able to merged well in the company Operating System.

- Lean tools Implementation Fous upon “imitating” Toyota Success.

- The outcome of Lean framework not able to transalted to company competitive advantages nor financial.

Lean Is not all about profit instead it is all about cultural shift.

One of most famous model Of lean system were Shingo model. Since lean not always about benefit It was about Culture. We need to able to see correlation between Guiding Principle of the Company alignment with the System to Select most practical Lean tools, to achieve overall Result.

Lean Manufacturing Principles Third misconception : Implement pull systems & reduce wastes new KPI.

as the headline above mention, yes itis quite Cringey. However those aro Quite accurate since that’s how management book written and fought over last twenty decades.

“We cannot improve What we were not measure”,

those Quote from Edward Deming haunted top management to manaya Operations. To asses lean framework by few Key Performance Indicator may led to Island of Success.

Lean principles Fourth misconception : A continuous pursuit of perfection or New Project.

In the grand symphony of corporate ideals, the fourth movement often echoes with the melodic strains of a continuous pursuit of perfection through a perpetual influx of new projects. This misconception, akin to a never-ending sonata of operational utopia, unfolds as a satirical commentary on the whimsical notion that perfection can be attained through an unceasing cascade of endeavors. Executives, donned in metaphorical capes of optimism, proclaim, “Behold our latest project! This time, we shall ascend to operational heights where inefficiency dare not tread, and our processes shall rival the intricacy of a Swiss timepiece.”

The continuous pursuit of perfection through an unbroken succession of new projects becomes a spectacle, reminiscent of a never-ending Shakespearean play where each act promises a climax that remains elusive, akin to Hamlet pondering the meaning of perfection. In this whimsical narrative, employees, ever resilient in the face of perpetual change, eagerly unwrap each new project like children on Christmas morning. The excitement is palpable, the anticipation akin to unwrapping a gift that promises to be the panacea for all operational woes. The corporate lexicon evolves to accommodate this satirical reality, introducing terms such as the “Project Symphony,” where each initiative is seen as a harmonious note contributing to the grand opus of operational excellence.

Conclusion:

In conclusion, the significance of lean manufacturing principles cannot be overstated, as evidenced by the substantial growth in research attention, with over 313,799 papers available on Academia.edu. Understanding and implementing these principles are crucial for achieving operational excellence. However, as our experience as lean facilitators reveals, there are common misconceptions that can hinder successful lean framework implementations.

The five core lean manufacturing principles—identifying value from the customer perspective, mapping the value stream, aligning the flow, implementing pull systems, and continuous improvement—form the foundation of lean practices. The roots of lean can be traced back to the Toyota Production System and its evolution, emphasizing hands-on practice and continuous refinement.

Despite the potential for lean manufacturing to revolutionize operations, misconceptions often arise during implementation. One significant misconception involves the misinterpretation of value. Management’s perception of lean as a tool solely for cost reduction can undermine its true purpose—to align with customer needs and create value.

Another misconception centers around the focus on cost reductions within the value stream. While cost benefits are important, the sustainability of lean transformations depends on a broader perspective that considers cultural shifts, long-term benefits, and organizational alignment.

The implementation of pull systems and the reduction of wastes, often measured through new Key Performance Indicators (KPIs), can be misunderstood. Simply relying on a limited set of KPIs may lead to a superficial understanding of lean success and hinder the achievement of long-term goals.

Finally, the continuous pursuit of perfection through new projects is a misconception that needs careful consideration. Lean is not just about launching new initiatives; it is a cultural shift that requires the alignment of company guiding principles with practical lean tools.

In essence, successful lean manufacturing implementation goes beyond short-term cost reductions. It involves embracing a cultural shift, aligning with customer perspectives, and sustaining improvements over the long term. As organizations continue to explore lean principles, debunking these misconceptions becomes paramount for realizing the true potential of lean manufacturing in enhancing efficiency, reducing waste, and fostering continuous improvement.

Tags: lean manufacturing

Aji

Hi there welcome to leandemy.com, with decade of experience in lean and manufacturing I'd love to share ideas and know how to better understand of lean practice

Related Posts

Scientific Thinking: Navigating between fact in statistics and human psychological bias

Understanding How the Human Brain Shapes — and Sometimes Sabotages — Operational Problem Solving If you’ve worked in manufacturing long enough, you’ve probably faced it: the same downtime keeps reappearing, the same quality defect creeps back,...

Eight Disciplines Problem Solving : Navigating Bias trough structured framework

When the Brain Becomes the Hidden Defect and decline Company sales revenue There a lot of cases where in B2B business poor customer experience and Quality issue cause the sales decline. in a survey of 1,350...

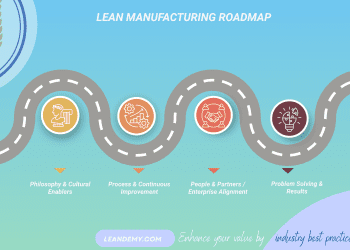

Lean Manufacturing Roadmap : Your Guide to Start the Transformation Journey

Introduction: Why You Need a Roadmap Before Starting Lean If you’ve been working in manufacturing, you’ve probably heard the buzz about “Lean Manufacturing.” It’s not just a trend — it’s a philosophy that helps...

Six Sigma vs AI: Future Talent Outlook in Continuous Improvement

Are You Lean practicioner within manufacturing industry? if yes you will notice that In all manufacturing sector the outlook of AI implemntation were growing According Research by Fortune bussiness insight , The global “AI in manufacturing”...

How to Make Hoshin Kanri X Matrix (Step-by-Step Guide)

How to Make Hoshin Kanri X Matrix (Step-by-Step Guide) Is your team great at hitting targets -- Just not the right one? Do your KPI's Change more often than your Machine changeovers? Ever feel like the...

Leader Standard Work Benefit: How to lead without falling for your own biases

Leader standard work benefit for manager is exercised to reduce your biases during decision making you will ask me how? when we think about a leader we often think about sharp mind, Quick instincts and Solid...

Please login to join discussion

ADVERTISEMENT