No products in the cart.

Lean manufacturing tools : Top 20 lean tools & Ultimate guide [Updated 2024]

A Guide to select lean manufacturing tools base on your Business process

Reading Time: 8 mins read

0

816

SHARES3.9k

VIEWSWant to improve your business or Process, however lost in which Lean manufacturing tools needed? Or you are wondering does lean manufacturing is it still relevant ?.

Throughout history of lean it was proven tools to boost company profitability. Lean manufacturing by enabling value driven focus throughout all layers. To make good lean program & implementation we need to know which and when to use lean manufacturing tools Based on your added values to customers.

Since the customer propositions and our business competitive advantage define the company operations and financials. Whether your production process or logistic transportation business, or even project management consultancy. It all the variable that will affect the lean manufacturing tools efficiency and efficacy since it will make different workflow and material flow.

Read our blog post That Cover Top 20 Lean tools list & ultimate guide to select the most relevant

The lean tools list

Here is our complete compilation of lean tool list, together with description of the tools

- 5S lean manufacturing

- Gemba (the actual palace)

- Visual Management

- 7 wastes ( Muda)

- Standardized work

- Andon

- Poka yoke (Error Proofing)

- Line balancing

- Total Productive maintenance

- Overall Equipment Effectiveness

- Single minute exchange dies

- Built In Quality

- Kaizen

- A3 problem solving (Root cause analysis using A3 format)

- Heijunka (level Scheduling)

- Just In Time

- Kanban (pull system)

- Kamishibai Boards

- Value stream mapping

- Hoshin Kanri (policy deployment)

Better understand about the tools we describe each tool briefly below:

5s Lean manufacturing

It was abbreviation of short, set-in order, standardize, shine, sustain and sometimes there adding with the last safety. this tool is important if you want to implement lean manufacturing in your production process to ease identify nonvalue add and waste in your process. since its aim to put only needed items are in workplace. See our post to get detail regarding the 5s audit or 5s audit step.

Gemba Walks

the term means go to actual place, it was one of most famous tools in lean manufacturing. why? in the first place it easy to practice but it also easy to fail. However, Gemba walks can be less effective if the element support were not put in place. For detail how to do effective gemba walk

Visual Management

One of easy to implement lean manufacturing were visual management. Visual management was standard put in workplace to identify ideal condition, such as where to put material incoming, Finished goods also defected product which usually in red zone. Visual management can be identified as color in floor or line mark in machine to identify certain center lining. To get a glimpse about visual control go to our article here

7 wastes (Muda)

the term was japanese meaning waste or non-value add job. it often described easily as 7 type of waste which is:

- Defect

- Over-production,

- Waiting,

- Transporting

- Inventory

- Motion

- Over Processing

for each waste analysis see our article here

Standardized work

Standardization eliminates variability in processes, ensuring that tasks are performed consistently across the board. This consistency leads to predictable outcomes, reduces errors, and enhances quality. By establishing a baseline for performance, standardized work provides a clear benchmark against which improvements can be measured.

Andon

Andon means signal, it is signal that identify any abnormalities within line production. The idea was to give prompt measure for respective team to help the line promptly. Andon implementations are good in manufacturing which has continuous flow and less likely in cell type or workshop type manufacturing. to see detail regarding andon system visit our article regarding andon

Poka Yoke

Poka yoke means error proofing tools, to prevent error operation by manpower. Hence as one of critical tools to develop Built in quality program to assure defect found early on. when it sounds simple the implementation can be daunting. to see details about Poka yoke see here.

Line Balancing

Line Balancing using yamazumi chart are ideal for company that are labor intensive. the yamazumi chart also can be modified with Gantt chart to analyze man – machine time series to identify OPE overall people effectiveness. detail implementation and discussion are in our post here

Total productive maintenance

Total productive maintenance are activities that involving operators in the line actively engage in maintenance task related with machineries they used. The main Idea were to prolong the Machine & it spare par lifetime from forced deterioration. The key activities were including cleaning the machine, inspections and lubrication, but the common failure was to develop operator skill level and we cover those part in our article about TPM here.

Overall Equipment Effectiveness

Overall equipment effectiveness is Key performance indicator in production line that indicates how well we are using the equipment inside factory. In fact, the idea already captured in early 1960’s where assembly line begun to implement. Even though it has been almost 60 years not all manufacturing or industry are familiar with this KPI to better understand OEE see our article here

Single minute exchange dies

Single minutes exchange dies, or the buzzword were SMED, yes you call it SMED little bit similar with Smurf. The Key element of SMED is to see nonvalue add job within changeover and optimize parallel work. SMED works well if we combine with VSM to improve flexibility of manufacturing, to see example of SMED go to our article here

Built In Quality

Built in quality are main program to reduce waste in defects, by ideas BIQ (the buzz words) are prevent defect outflow from process to process then creating huge cost of poor Quality (CoPQ). One of way to measure were trough FTR, to see detail please see here.

Kaizen

Kaizen are quick event to improve line of machine. The idea is to have spontaneous improvement ideas with cross function team and the operator line. The Idea of blitz kaizen were to give fresh prespective of operator machine from other view. If you plan to do Blitz kaizen visit our post here

A3 problem solving (Root cause analysis)

One of tools are refined times by times were Root cause analysis or RCA by using A3 format. Why it matters? because it eases yet precise application in manufacturing and proven effective to develop member sense of problem solving which later on described as 8D report in another region. please see our review regarding A3 form used by Tota here.

Heijunka (level Scheduling)

what happens when we follow order from customer, it might be chaos in term of workload. Because there will be seasonality in term of customer order, then how about we make high buffer which not sure when it being purchased. If you remember stock also become waste that reducing company cashflow, and also not even utilization or saturation are waste of non-used personnel. To answer those are using Heijunka or level scheduling to minimize stock and to get faster in term of total product delivery time. Heijunka works well to improve cash flow in company but also many fails to do it. To better understand about Heijunka visit our post here.

Just In Time

when Heijunka mention about the time frame using level schedule Just in time measure the least Work in progress as possible between process. As one of the wastes is in inventory the idea was to get zero inventory from customer to our factory. When it may sound impossible for repetitive order, actually this kind of system are quite often used in industry where the products are depends on customer such as jewelry, tailor, medium voltage cable and many more. to Better understand about Just in time principle, see our post here.

Kanban

Kanban means card, that contain information about how many orders should be made to fulfill the customer. It well known as pull system and easily identify as make to order type process, rather than push system which made production as much as possible when it might increase defect, Inventory and also constrain the capacity. to better understand regarding Kanban and how it implemented visit our page regarding what is kanban or kanban card.

Kamishibai Borads

Kamishibai means paper play! yes, it is one of japanese arts. However, toyota use those term for audit board as one of Visual management tools that can identify abnormalities easily. Kamishibai Boards contain cards that identify items needs to be done, checked by standard daily, weekly or monthly. This card had two sides which coloring green & red. when the red faced outwards and visible to people near the boards it contain information that something not right. TO get a better view about kamishibai Boards please see our article here.

Value stream map

Value stream mapping are hollistics approcah to find out where are our loses , capacity constrain, our highest inventory level in the line production. The tools works well if we can get Good OEE actual data , days inventory and the most important is customer takt time. VSM also can be made as master plan how we can catch up with JIT system by analyzing loses from each line. Here our template of VSM and how to make good VSM study.

Value Stream Mapping symbols : From Clarity to Chaos The Unintended consequences

Value Stream Map Example : Case study vital metrics you need to know before starting VSM

Hosin Kanri

The terms mean of Policy deployment, this is final form of lean in the manufacturing organization. Where the organization understand what are key take aways to sustain & grow the business and also deploy the policy from each level of the management. The event usually held in last quarter of fiscal year or sometimes 5 year plan of the organization, which previously analyzed problem faced by A3 Report. To learn and implement more about Hoshin kanri see our post here.

those are 20 items about lean tools if there any tems of Lean you might know see our other post to see other related topic dont forget to share or subscribe

Tags: Lean Tools

Aji

Hi there welcome to leandemy.com, with decade of experience in lean and manufacturing I'd love to share ideas and know how to better understand of lean practice

Related Posts

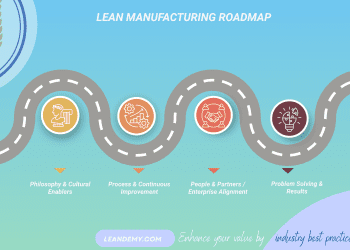

Lean Manufacturing Roadmap : Your Guide to Start the Transformation Journey

Introduction: Why You Need a Roadmap Before Starting Lean If you’ve been working in manufacturing, you’ve probably heard the buzz about “Lean Manufacturing.” It’s not just a trend — it’s a philosophy that helps...

A3 Problem Solving Ultimate Guide : Decoding Rootcause with 7 step 7 tools

A3 problem-solving Templates are one of lean manufacturing tools. It has practical ways to un woven complex issues. In the complex world of business operations, problems are inevitable. Whether they are small hiccups or significant hurdles,...

Hoshin Kanri : Translating Your Business Strategy into Roadmap

How Hoshin Kanri Can Steer Your Business Strategy Are you : Feeling lost at sea with your business goals? Staring at a strategic plan that feels disconnected from daily operations? If so, then Hoshin Kanri might...

Visual Management in the Operation : The Navigating Clarity in dynamic workplace

Visual management is the game-changer you didn't know your workplace needed! Imagine a world where everyone's on the same page, errors are minimized, and communication flows seamlessly—that's the power of visual management. In simple terms, visual...

A Comprehensive Guide to Total Productive Maintenance

In today's fast-paced industrial landscape, maximizing productivity while minimizing downtime is crucial for success. One approach gaining traction is Total Productive Maintenance (TPM), a proactive maintenance strategy aimed at optimizing equipment effectiveness. Recent studies converge...

Kaizen: The Power of Shifting Mindset & Domino effect towards efficiency

Kaizen often mentioned methodologies which leverage the bussiness. In the dynamic landscape of manufacturing, businesses are constantly seeking ways to enhance efficiency, productivity, and overall performance. One approach that has gained significant traction in recent years...

Please login to join discussion

ADVERTISEMENT