No products in the cart.

Takt Time: How One Metric Can Transform Your Business Performance

Reading Time: 6 mins read

0

751

SHARES3.6k

VIEWSTakt Time vs. the Bullwhip Effect: Untangle the Mayhem Within Your Supply Chain

“Takt Time” emerges as a pivotal metric, capable of transforming business performance.because of dynamic landscape of supply chain and persistent challenge known as the “bullwhip effect.” Demand amplification, colloquially termed the “bullwhip effect,” is not a new phenomenon.This phenomenon incurs substantial costs, from capacity on-costs and stock-out costs during the upswing to stockholding and obsolescence costs on the downswing.

The bullwhip effect, explored in a study published in Transportation Research Part E: Logistics and Transportation Review (source), remains a formidable force within the intricate web of supply chain dynamics. takt time is an simple metric acts as a compass, guiding your production towards smooth, predictable flow and untangling the knots created by the bullwhip.

So, what exactly is this magical measure, and how can it transform your business performance?

What is Takt Time? The Sliding Paradigm Unveiled

According to Merriam webster dictionary The word takt meaning a beat or pulse in music. The word came from German word

Takt time, in its simplest form, is the pace at which you must produce to meet customer demand on time, every time. It is also tools to inherent lean principles which is one piece flow. Introduced by toyota to reduce the stock of inventory raw material.

Raw materials are top 3 cost in one of automotive total cost per car which can consist more than 50%. By implementing one piece flow as the customer demand and eliminate buffer. The cost turnover will be better.

Here some illustration of takt time, Imagine it as a rhythmic heartbeat for your production process. It is calculated by dividing your available production time by the total customer demand you need to fulfill during that period. For example, if you are having an hot dog stall, which have 8 hours of operational time and average daily you need to produce 100 hot dog in a day, your takt time would be 4.8 minutes per hot dog.

Think of takt time as a sliding door at a busy grocery store. Customers arrive at a steady pace, and the door opens and closes just in time to let one person through. Similarly, your production should operate at a pace that allows you to complete one unit exactly the time the next demand arrives. This eliminates waiting, overproduction, and the dreaded bullwhip effect.

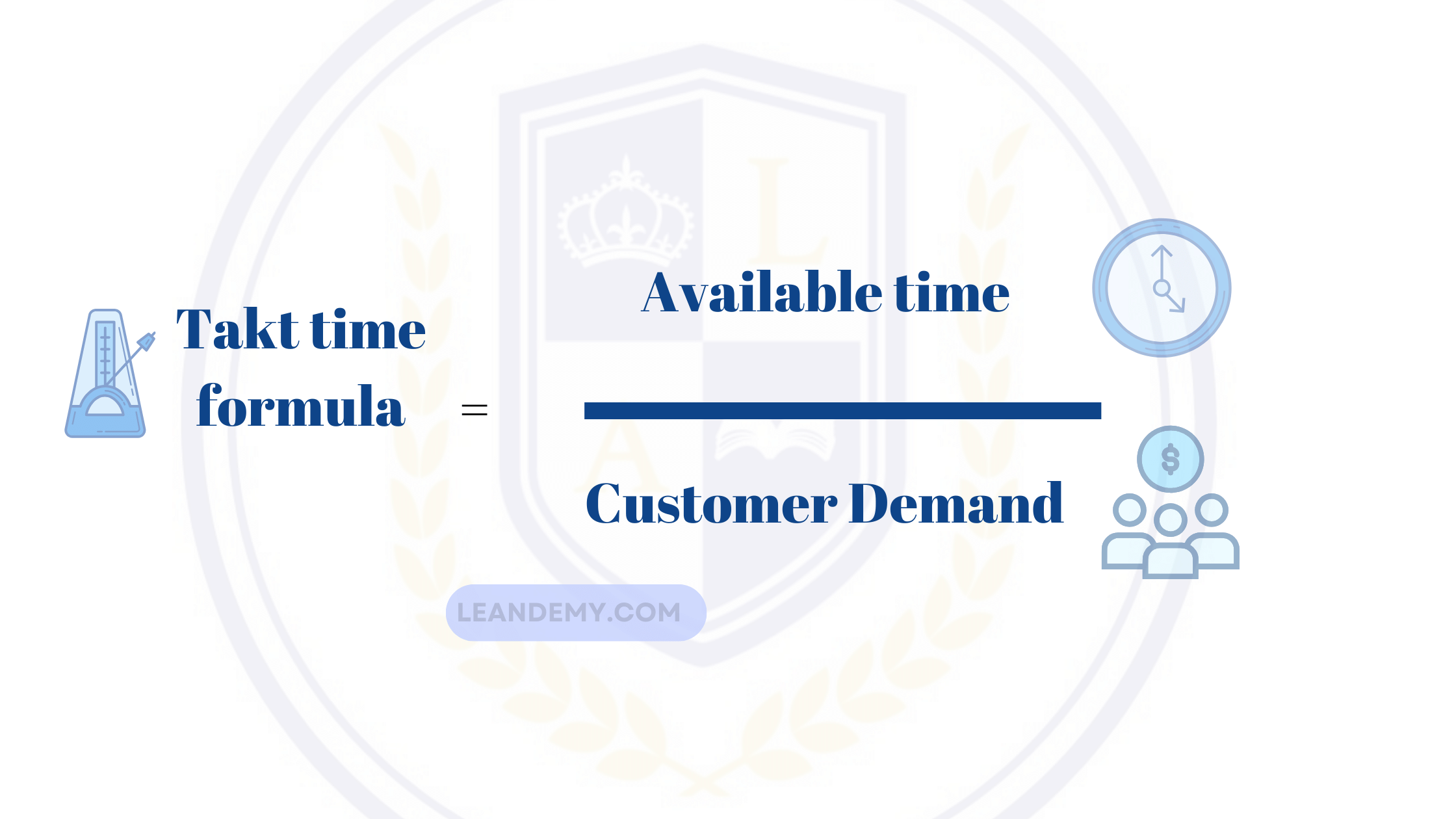

Takt Time Formula: The Metric that Saves Countless Businesses

Takt time formula , many people quite unclear about how to calculate takt time. Here we give clarity about the takt time formula.

Takt Time = Available Production Time / Total Customer Demand

It’s important to consider all available production time, including scheduled breaks, maintenance periods, and even set-up times. For total customer demand, use an accurate forecast, preferably averaged over a specific period to account for fluctuations.

Now, the magic happens once you implement takt time. Every aspect of your production process – from lead times to batch sizes, staffing levels to work-in-progress limitations – gets re-evaluated and adjusted to align with your new guiding star. The result? A synchronized symphony of production, delivering just what you need, when you need it.

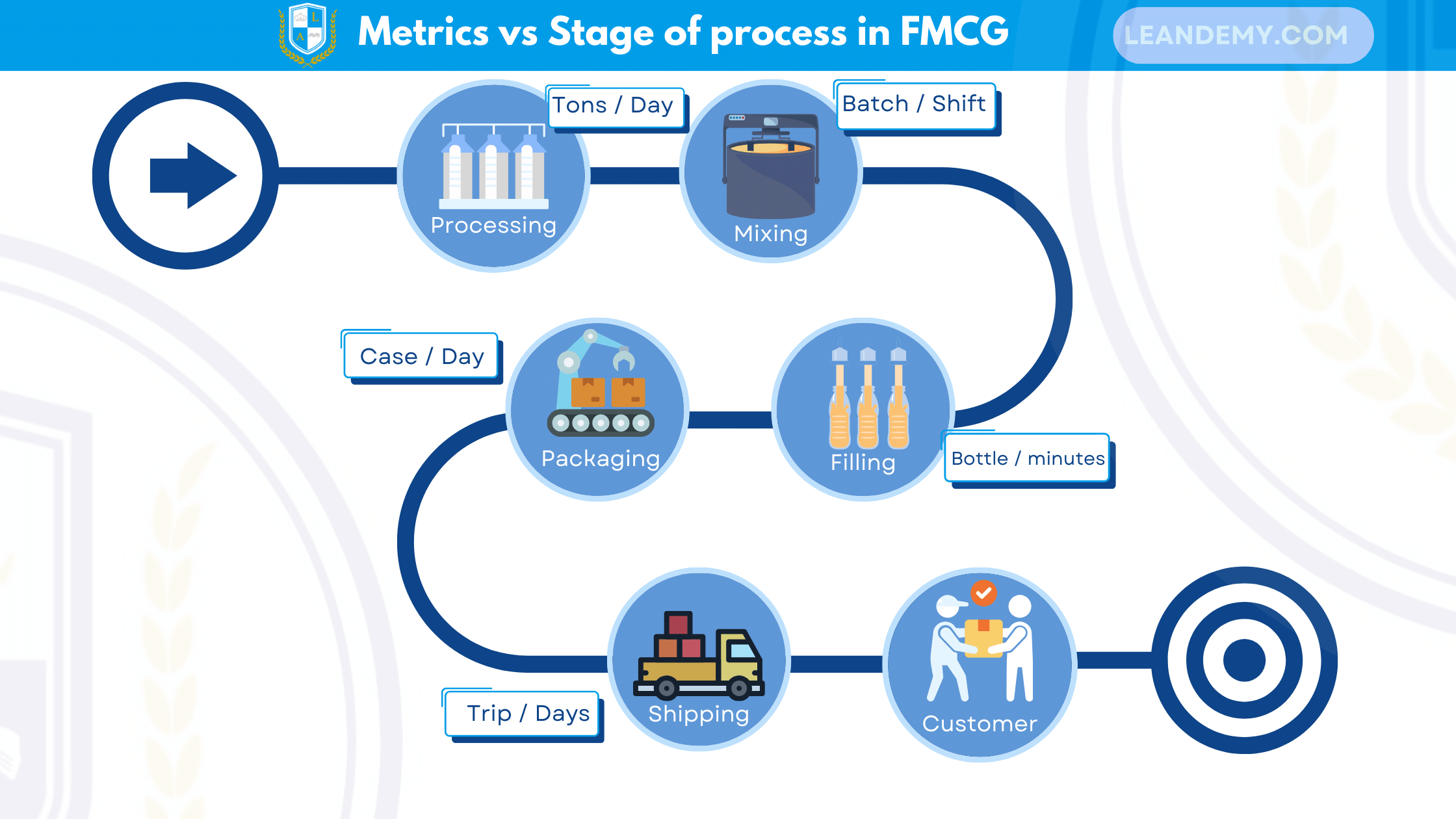

Takt time in Chemical process or Fast moving consumer Goods

Many of people quite confused with concept of takt if applied in Batch Processing manufacturing industry. Since in the upstream it produced by batch of certain volume of the silo. The down stream produced by different unit such as piece or cases of product shipment.

To clarify those things the takt time calculated based on what customer get. In other word if you are send your product in one cases in your customers. The takt time calculated by dividing the available time with customer demand converted the units in cases.

Since in Chemical industry and FMCG the finish good has various size category it is important to not use the mixed volume. Rather, you should specify the demand in each SKU.

Takt Time vs. Cycle Times: Mastering the Lean Manufacturing Metrics

Don’t confuse takt time with cycle time. Cycle time is the actual time it takes to complete one unit of production. While these metrics seem similar, they serve different purposes. Cycle time tells you how efficient your process is within itself, while takt time guides you towards meeting customer demand.

Think of it this way: Imagine baking cookies. The time it takes you to mix the dough, roll it out, and cut the cookies is your cycle time. But if you only bake them at a pace that satisfies your daily craving, ignoring upcoming family gatherings and birthday parties, you’ll soon be facing both empty trays and disappointed guests.

Implementing the metric: The seed of Lean Transformations

Takt time is the cornerstone of Lean manufacturing principle, a philosophy focused on eliminating waste and optimizing flow. By aligning all processes with takt time, you achieve:

- Reduced lead times: Products move through the system faster, satisfying customer needs quicker.

- Improved inventory management: No more overstocking or understocking, just the right amount of materials at the right time.

- Enhanced workforce efficiency: Employees focus on value-adding activities, eliminating unnecessary waiting and unproductive time.

- Greater agility: Responding to demand fluctuations becomes easier, protecting you from the bullwhip effect.

Implementing takt time isn’t always easy. It requires dedication, commitment, and often a cultural shift within your organization. But the rewards are undeniable. With takt time as your guide, you can transform your business from a chaotic marketplace into a well-oiled machine, delivering consistent value to your customers and propelling yourself ahead of the competition.

Value Stream Mapping: The bigger picture of takt time metrics

Value Stream Mapping (VSM) is a powerful tool in lean manufacturing for identifying areas of improvement in the production process. It helps visualize the flow of value from raw materials to customers and highlights opportunities to eliminate waste and enhance efficiency. The core principles of VSM include transparency, a strategic approach, and the elimination of waste while implementing pull systems.

If yo take a look from the VSM symbols which is process block icon the tackt time are the pivot metrics as from the VSM Example above initiated. Takt time converts WIP, Non value Add time and create the overall VA & NVA landscape. Without takt time the summary of current state Value stream map cannot be concluded.

Conclusion

Takt time is not just a metric; it’s a philosophy, a mindset that reshapes how you approach production and customer satisfaction. It’s the antidote to the bullwhip effect, the steady hand on the rudder guiding your business towards a calm and profitable sea. Embracing takt time may mean challenging established practices, but the rewards of predictable flow, reduced waste, and happy customers are worth the journey.

Here are some additional tips for implementing takt time in your organization:

- Start small: Choose a pilot project or a specific product line to begin with. This allows you to test the waters and iron out any wrinkles before a full-scale rollout.

- Get buy-in from all levels: From executives to the shop floor, everyone needs to understand and support the takt time initiative. Communication and training are key.

- Measure and adjust:Continuously monitor your takt time and make adjustments as needed. Remember, it’s an ongoing process, not a one-time event.

- Celebrate successes: When you achieve takt time goals, celebrate them! This reinforces the importance of the initiative and keeps everyone motivated.

Takt time may seem like a simple concept, but its impact can be profound. By aligning your production with the rhythm of customer demand, you unlock a hidden potential for efficiency, agility, and customer satisfaction. So, are you ready to step into the world of takt time and transform your business performance?

Aji

Hi there welcome to leandemy.com, with decade of experience in lean and manufacturing I'd love to share ideas and know how to better understand of lean practice

Related Posts

Scientific Thinking: Navigating between fact in statistics and human psychological bias

Understanding How the Human Brain Shapes — and Sometimes Sabotages — Operational Problem Solving If you’ve worked in manufacturing long enough, you’ve probably faced it: the same downtime keeps reappearing, the same quality defect creeps back,...

Eight Disciplines Problem Solving : Navigating Bias trough structured framework

When the Brain Becomes the Hidden Defect and decline Company sales revenue There a lot of cases where in B2B business poor customer experience and Quality issue cause the sales decline. in a survey of 1,350...

Lean Manufacturing Roadmap : Your Guide to Start the Transformation Journey

Introduction: Why You Need a Roadmap Before Starting Lean If you’ve been working in manufacturing, you’ve probably heard the buzz about “Lean Manufacturing.” It’s not just a trend — it’s a philosophy that helps...

Six Sigma vs AI: Future Talent Outlook in Continuous Improvement

Are You Lean practicioner within manufacturing industry? if yes you will notice that In all manufacturing sector the outlook of AI implemntation were growing According Research by Fortune bussiness insight , The global “AI in manufacturing”...

How to Make Hoshin Kanri X Matrix (Step-by-Step Guide)

How to Make Hoshin Kanri X Matrix (Step-by-Step Guide) Is your team great at hitting targets -- Just not the right one? Do your KPI's Change more often than your Machine changeovers? Ever feel like the...

Leader Standard Work Benefit: How to lead without falling for your own biases

Leader standard work benefit for manager is exercised to reduce your biases during decision making you will ask me how? when we think about a leader we often think about sharp mind, Quick instincts and Solid...

Please login to join discussion

ADVERTISEMENT