No products in the cart.

A Comprehensive Guide to Total Productive Maintenance

Reading Time: 9 mins read

0

777

SHARES3.7k

VIEWS

In today’s fast-paced industrial landscape, maximizing productivity while minimizing downtime is crucial for success. One approach gaining traction is Total Productive Maintenance (TPM), a proactive maintenance strategy aimed at optimizing equipment effectiveness.

Recent studies converge on the view that integrating TPM and Six Sigma offers synergistic gains—TPM ensures machine reliability and workforce engagement, while Six Sigma statistically optimizes process consistency. This hybrid framework has proven highly effective in manufacturing and service sectors alike

In this comprehensive guide, we’ll delve into the fundamentals of TPM, its benefits, the eight pillars that form its foundation, the twelve-step implementation process, real-world examples of companies successfully adopting TPM, and a concluding reflection on its significance.

What is Total Productive Maintenance ?

TPM is a holistic approach to equipment maintenance that involves everyone in the organization, from top management to frontline operators.

At its core, Total Productive Maintenance seeks to eliminate losses associated with equipment downtime, defects, and accidents, ultimately driving overall equipment effectiveness (OEE) to its maximum potential.

By focusing on preventive and predictive maintenance, TPM aims to create a culture of continuous improvement and operational excellence within an organization.

TPM vs Six Sigma: Key Differences in Approach

start by setting the stage: both Total Productive Maintenance (TPM) and Six Sigma aim to achieve higher efficiency, reduced downtime, and consistent quality. both of operation al excelelnce apporach to achieve higher efficiency and lower production cost. TPM and six sigma DMAIC are widely used methodology within manufacturing even on today appliaction in wide range sector such as pharmaceuticals, fast moving consumer goods, enery / chemicals.

in most cases industry that rely on 24/7 operation such as chemicals factory deploy approach towards TPM. and while organization that has product from natural resurces deploy six sigma since there were variation within processes

trough the similar goal the approah were slightly diffrent while TPM start from hollisticss function and deploy as pillar chang agent . whil six sigma start by focusing from the organization biggest bleeders.

while in short run six sigma always shown bigger fiancial impacts in loger run TPM were much more desireable since it is ensure the organization stability and sustenance towards operational excellence

| Aspect | TPM | Six Sigma |

|---|---|---|

| Core Focus | Equipment & maintenance | Process & quality variation |

| Key Method | Autonomous & planned maintenance | DMAIC problem-solving |

| Goal | Zero breakdowns | Zero defects |

| Tools | OEE, 5S, Kaizen | Statistical analysis, control charts |

| Ownership | Pillar Owner | Cross-functional project teams |

1️⃣ Shared Vision: Driving Operational Excellence

Both Total Productive Maintenance (TPM) and Six Sigma share a common purpose — achieving higher efficiency, quality, and reliability. While TPM focuses on maximizing equipment effectiveness through preventive and autonomous maintenance, Six Sigma aims to reduce process variation using data-driven problem-solving.

Academic reviews, such as Jain et al. (2014) and Singh et al. (2018), highlight TPM’s strength in cultivating operator ownership and boosting Overall Equipment Effectiveness (OEE) through structured maintenance pillars. TPM creates a culture where every employee contributes to machine reliability, forming the foundation for sustainable improvement.

2️⃣ Different Roads to the Same Goal

The two frameworks differ in their approach and tools. TPM is people-centric — built around maintenance discipline, continuous involvement, and zero breakdowns. Six Sigma, on the other hand, is analytical and data-centric, structured around the DMAIC cycle to identify and eliminate root causes of defects.

Studies like Raval & Kant (2017) and Kaouthar (2020) confirm that TPM focuses more on equipment reliability, whereas Six Sigma zeroes in on process variation and defect reduction. TPM uses metrics such as OEE and downtime, while Six Sigma relies on Defects per Million Opportunities (DPMO) and statistical analysis.

Here’s a quick comparison:

| Aspect | TPM | Six Sigma |

|---|---|---|

| Core Focus | Equipment reliability | Process quality |

| Approach | Preventive, people-driven | Analytical, data-driven (DMAIC) |

| Key Metric | OEE | DPMO / Sigma Level |

| Goal | Zero breakdowns | Zero defects |

3️⃣ Integration: The Best of Both Worlds

Recent research underscores that integrating TPM and Six Sigma leads to measurable performance gains. Sharma (2014) demonstrated that blending TPM’s preventive culture with Six Sigma’s statistical rigor enhances productivity and reduces variability — especially in SMEs. Similarly, Burawat (2019) found that combining Lean Six Sigma, TPM, and 5S significantly improved workflow efficiency and reduced rework costs.

The key takeaway: TPM builds reliability; Six Sigma refines performance. Together, they create a synergistic improvement model that strengthens both equipment and process excellence — the dual engine of modern manufacturing competitiveness.

4 Benefits of Total Productive Maintenance

The benefits of implementing TPM are manifold.

1. Foster structured approach for equipment maintenance comprehensively

Total Productive Maintenance (TPM) facilitates a structured and comprehensive approach to equipment maintenance, ensuring the reliability and longevity of critical assets. By integrating preventive and predictive maintenance practices into daily operations, TPM enables organizations to proactively address maintenance needs before they escalate into costly breakdowns.

Focus upon CAPD method

Through the establishment of standardized maintenance procedures and schedules, TPM fosters consistency and accountability across maintenance activities. This structured approach not only minimizes unplanned downtime but also optimizes overall equipment effectiveness (OEE), enhancing productivity and profitability. By systematically identifying and addressing maintenance requirements, TPM empowers organizations to maximize the value of their assets while minimizing the risk of disruptions to production processes.

2. Engage operators to proactively maintain their working equipment

One of the key benefits of Total Productive Maintenance (TPM) is its ability to engage frontline operators in the maintenance of their working equipment. By empowering operators to take ownership of routine maintenance tasks, TPM fosters a culture of proactive equipment care and accountability. Operators are trained to conduct inspections, perform lubrication, and execute minor repairs, enabling them to identify and address issues in real-time.

Autonomous Maintenance is the aim of Total Productive Maintenance

This proactive approach not only reduces reliance on centralized maintenance teams but also facilitates early intervention and problem-solving. By leveraging the expertise and familiarity of operators, TPM ensures that equipment is maintained at peak performance levels, minimizing the risk of unexpected failures and optimizing production uptime.

Ultimately, by engaging operators in the maintenance process, TPM enhances operational efficiency and cultivates a sense of pride and ownership among employees.

3. Early detection of equipment performance deterioration

Total Productive Maintenance (TPM) enables organizations to achieve early detection of equipment performance deterioration through continuous monitoring and analysis. By implementing condition-based maintenance techniques and leveraging predictive maintenance technologies, TPM allows organizations to identify potential issues before they impact production.

Through the use of sensors, data analytics, and predictive modeling, TPM provides insights into equipment health and performance trends, enabling proactive intervention.

This early detection capability minimizes the risk of equipment failures and unplanned downtime, ensuring uninterrupted production operations. By addressing issues in their early stages, organizations can extend the lifespan of equipment, reduce maintenance costs, and optimize overall equipment effectiveness (OEE). Ultimately, early detection of equipment performance deterioration is a key benefit of TPM, enabling organizations to maintain peak operational performance and competitiveness.

4. Maintain critical points related to risk of defects and safety incidents

Total Productive Maintenance (TPM) plays a crucial role in maintaining critical points related to the risk of defects and safety incidents within manufacturing environments. By implementing rigorous maintenance practices and quality control measures, TPM helps mitigate the risk of equipment malfunctions and production errors that could lead to defects.

Total Productive Maintenance as hollistics angle of Safety quality and performance

Additionally, TPM emphasizes the importance of safety protocols and procedures to prevent accidents and injuries in the workplace. Through proactive maintenance activities and regular inspections, TPM ensures that equipment is operating within specified parameters and that safety mechanisms are functioning effectively. By addressing potential risks and vulnerabilities, TPM helps safeguard both product quality and employee well-being.

Zero loss mindset

This proactive approach not only reduces the likelihood of costly product recalls and rework but also fosters a culture of safety consciousness and continuous improvement. Ultimately, by maintaining critical points related to defect and safety risks, TPM enables organizations to uphold quality standards, protect their reputation, and ensure the well-being of their workforce.

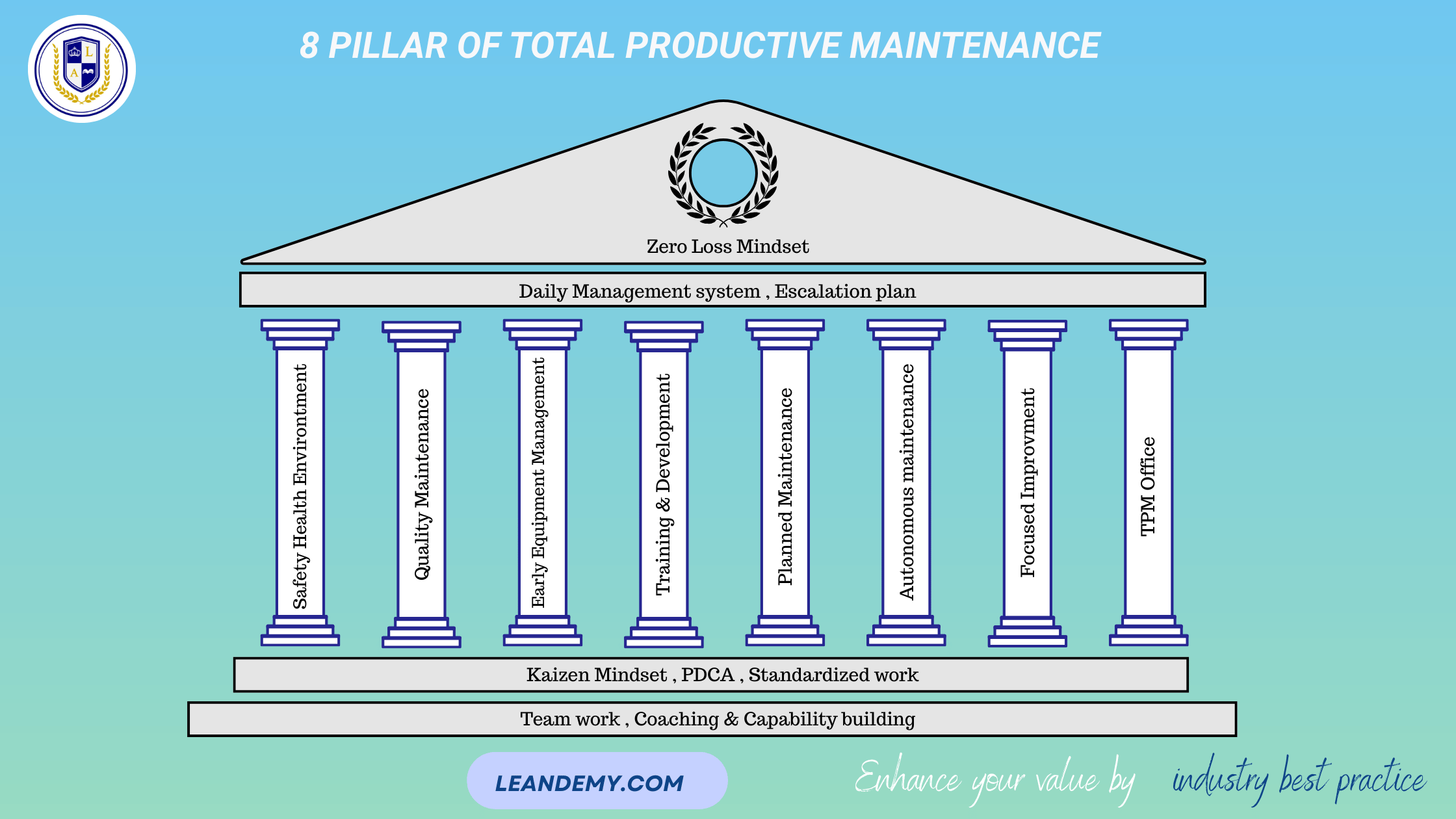

The Eight Pillars of Total Productive Maintenance

TPM rests on eight foundational pillars, each serving as a cornerstone for operational excellence. These pillars include:

1. Focused Improvement (Kobetsu Kaizen)

Focused Improvement, known as Kobetsu Kaizen in Japanese, serves as a pivotal pillar within the Total Productive Maintenance (TPM) framework. It revolves around the concept of continuous improvement, targeting specific areas within the organization for enhancement. By fostering a culture of innovation and problem-solving.

Focused Improvement encourages teams to identify inefficiencies, eliminate waste, and streamline processes. Through structured methodologies such as A3 problem solving and value stream mapping, organizations can systematically tackle issues and drive incremental improvements in productivity, quality, and overall performance.

2. Autonomous Maintenance (Jishu Hozen)

Autonomous Maintenance, or Jishu Hozen, empowers frontline operators to assume responsibility for the upkeep and minor repairs of equipment. This pillar emphasizes the importance of proactive maintenance activities carried out by those closest to the machinery on a day-to-day basis.

By engaging operators in routine inspections, lubrication, and cleaning tasks, Autonomous Maintenance aims to prevent breakdowns, reduce downtime, and prolong equipment lifespan. by using kamishibai board to visualized AM completions. Moreover, it fosters a sense of ownership and pride among employees, promoting a culture of accountability and continuous improvement throughout the organization.

3. Planned Maintenance (Keikaku Hozen)

Planned Maintenance, also known as Keikaku Hozen, focuses on the systematic planning and scheduling of maintenance activities to optimize equipment reliability and performance. This pillar advocates for the implementation of preventive and predictive maintenance strategies based on data-driven insights and historical equipment performance.

By proactively addressing potential issues before they escalate into major failures, Planned Maintenance helps minimize unplanned downtime, reduce repair costs, and extend equipment lifespan. Furthermore, it facilitates better resource allocation and workforce planning, ensuring that maintenance tasks are conducted efficiently and effectively.

4. Early Equipment Management (Seiketsu)

Early Equipment Management, or Seiketsu, emphasizes the importance of designing and implementing robust maintenance processes during the initial stages of equipment installation and commissioning. This pillar aims to identify and address potential reliability issues before they impact production operations. By ensuring that equipment is installed correctly, calibrated accurately, and operated within specified parameters, Early Equipment Management helps prevent premature failures and performance degradation. Moreover, it lays the foundation for ongoing maintenance activities, setting the stage for long-term equipment reliability and performance optimization.

5. Quality Maintenance (Hinshitsu Hozen)

Quality Maintenance, referred to as Hinshitsu Hozen, focuses on preserving equipment integrity to uphold product quality standards. This pillar recognizes the intrinsic link between equipment reliability and product quality, advocating for proactive maintenance practices to minimize defects and deviations.

By maintaining equipment in optimal condition and adhering to established quality control measures, organizations can mitigate the risk of production errors, rework, and customer complaints. Quality Maintenance not only safeguards product quality but also enhances customer satisfaction and brand reputation in the marketplace.

6. Training & development (Kyoiku)

Education and Training, or Kyoiku, play a crucial role in fostering a culture of competence, engagement, and continuous learning within the organization. This pillar emphasizes the importance of providing employees with the knowledge, skills, and resources they need to excel in their roles. By investing in comprehensive training programs, hands-on workshops, and knowledge-sharing initiatives, organizations can empower employees to perform their jobs effectively and contribute to the success of TPM initiatives. Moreover, Education and Training foster a sense of ownership and accountability for equipment maintenance, driving collective responsibility for operational excellence.

7. Administrative and Office TPM (Kobetsu Kaizen)

Administrative and Office TPM, also known as Kobetsu Kaizen, extends the principles of TPM beyond the shop floor to administrative processes and office environments. This pillar recognizes that inefficiencies and waste can occur in non-production areas as well, impacting overall organizational performance. By applying TPM principles such as standardized work, visual management, and continuous improvement to administrative workflows, organizations can streamline processes, eliminate bottlenecks, and enhance productivity. Administrative and Office TPM promote a culture of efficiency and effectiveness across all functions, driving sustainable improvements in performance and profitability.

8. Safety, Health, and Environment (SH&E)

Safety, Health, and Environment (SH&E) form the cornerstone of responsible and sustainable business practices within the TPM framework. This pillar prioritizes the well-being of employees, stakeholders, and the environment, recognizing that safety and environmental stewardship are integral to operational excellence. By implementing robust safety protocols, ergonomic practices, and environmental management systems, organizations can create a safe and healthy work environment while minimizing their ecological footprint. Moreover, SH&E initiatives enhance employee morale, reduce absenteeism, and mitigate the risk of regulatory non-compliance, ultimately contributing to long-term business success and social responsibility.

Each pillar plays a vital role in creating a sustainable TPM framework within an organization.

The Twelve Steps of TPM

Implementing TPM involves a systematic approach comprising twelve key steps, including:

1. Understanding the current situation

2. Establishing a steering committee

3. Setting objectives and targets

4. Training and education

5. Autonomous maintenance implementation

6. Planned maintenance system development

7. Early equipment management

8. Quality maintenance activities

9. Administrative TPM implementation

10. Safety, health, and environmental improvements

11. TPM office and infrastructure establishment

12. Overall evaluation and reflection

Each step is carefully designed to guide organizations through the TPM implementation process, ensuring its success and sustainability.

Companies Implementing Total Productive Maintenance

Numerous companies across various industries have successfully implemented TPM and reaped its rewards. For instance,

Toyota is renowned for its commitment to TPM, which has played a significant role in its renowned efficiency and quality.

Similarly, companies like Unilever, Procter & Gamble, and Coca-Cola have embraced TPM to optimize their manufacturing processes and enhance competitiveness.

Conclusion

In conclusion, Total Productive Maintenance is not just a maintenance strategy; it’s a philosophy that embodies continuous improvement, employee empowerment, and operational excellence. By focusing on preventive maintenance, engaging employees at all levels, and fostering a culture of accountability, organizations can unlock their full potential and thrive in today’s dynamic business environment. Embracing TPM isn’t merely an option—it’s a necessity for those striving to stay ahead in an increasingly competitive landscape.

Aji

Hi there welcome to leandemy.com, with decade of experience in lean and manufacturing I'd love to share ideas and know how to better understand of lean practice

Related Posts

Scientific Thinking: Navigating between fact in statistics and human psychological bias

Understanding How the Human Brain Shapes — and Sometimes Sabotages — Operational Problem Solving If you’ve worked in manufacturing long enough, you’ve probably faced it: the same downtime keeps reappearing, the same quality defect creeps back,...

Eight Disciplines Problem Solving : Navigating Bias trough structured framework

When the Brain Becomes the Hidden Defect and decline Company sales revenue There a lot of cases where in B2B business poor customer experience and Quality issue cause the sales decline. in a survey of 1,350...

Lean Manufacturing Roadmap : Your Guide to Start the Transformation Journey

Introduction: Why You Need a Roadmap Before Starting Lean If you’ve been working in manufacturing, you’ve probably heard the buzz about “Lean Manufacturing.” It’s not just a trend — it’s a philosophy that helps...

Six Sigma vs AI: Future Talent Outlook in Continuous Improvement

Are You Lean practicioner within manufacturing industry? if yes you will notice that In all manufacturing sector the outlook of AI implemntation were growing According Research by Fortune bussiness insight , The global “AI in manufacturing”...

How to Make Hoshin Kanri X Matrix (Step-by-Step Guide)

How to Make Hoshin Kanri X Matrix (Step-by-Step Guide) Is your team great at hitting targets -- Just not the right one? Do your KPI's Change more often than your Machine changeovers? Ever feel like the...

Leader Standard Work Benefit: How to lead without falling for your own biases

Leader standard work benefit for manager is exercised to reduce your biases during decision making you will ask me how? when we think about a leader we often think about sharp mind, Quick instincts and Solid...

Please login to join discussion

ADVERTISEMENT