No products in the cart.

Value Stream Mapping symbols : From Clarity to Chaos The Unintended consequences

Reading Time: 6 mins read

0

804

SHARES3.8k

VIEWSValue Stream Mapping symbols those iconic shapes and lines, play a crucial role in the VSM methodology. Which are considered a lean prestige tools and widely over promoted.

Not many people are aware of unintended consequences of implementing this tools. Value stream map are meant to simplify complex processes, facilitate understanding, and guide improvements.

However, based on our Experience a decade Implementing lean and VSM practice. We often encounter unexpected consequences that can turn clarity into chaos. It was happens so Often when we try to start Current State Value Stream Mapping.

Let’s explore these unintended outcomes and learn how to navigate them effectively in our article below!

Value Stream Mapping symbols: Complete symbols Guide & The Promise of Clarity

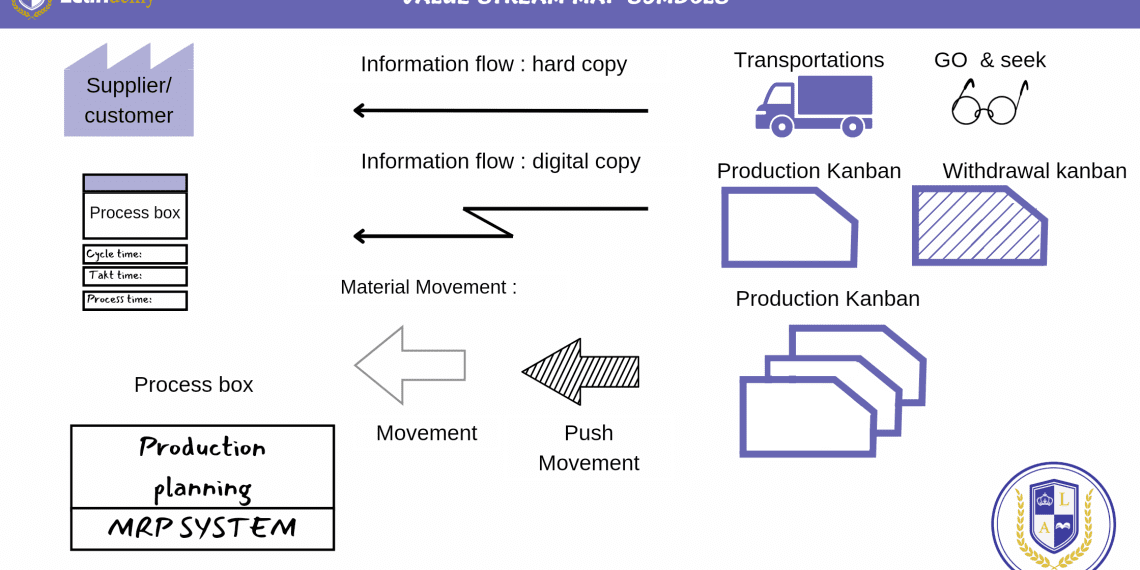

Below are VSM symbols in complete icon as a guide :

Value Stream Mapping is a visual tool designed to analyze wastages within an operation processes. Value Stream Mapping symbols are the visual language that helps teams understand, analyze, and improve their workflows. At first glance, these symbols appear to be the keys to unlocking process efficiency. However it were obviously tend to give miss lead in some many ways.

Here’s a quick overview of commonly used Value Stream Mapping symbols:

There are Some notes I Would like to give a highlight, that there are really few people that would be able to comprehend the VSM current state at a glance!

Even the seasoned lean Sensei will need time and. further explanations

Why?

there are two reasonable cause

first is We are not Using these kinds of symbols as staple ways of daily communication!.

Second things Were different perceptions on capturing on how it’s really happens.

Get our editable template of VSM symbols

VSM vs SCM : when Perfect fantasy world meets disruptive reality

Above is Illustration of Ideal Current State Value Stream map. It covers from Supplier to manufacturing processes and eventually Goes to Customers. It is Classical manufacturing processes which might be rarely find this day. As the Supply Chain technology evolve last decade, it has made real differences on how we operate currently.

One of or example is Inventories, more of the factory using vendors as warehousing to keep their Raw material. This due to surging inflations and need more area to manage more variance product. This may caused more complex informational flow, we might not able to iterate using one or two Symbols of informations as VSM standard.

On other parts there are chances that manufacturing stages outsourcing. In which particular Stages need to be dong in Vendors or 3rd party. For example In order to promoto their value of product, Fast moving Consumer Goods decided to join hands with other brand with similar value for bundling. For example vodka & coke bundling.

Those activities are being done after the finish Goods, or minght be processed in 3rd party vendors. Hows VSM capture those? Since pivotal bussiness strategy also happens in seasons ?meaning it need fast decisions and operations.

Bottom line there are no perfect VSM in ideal textbook which releasesd in late 1990’s anymore. Bussiness strategy and market shift, pusing Supply cain to has more efficacy. In order to cope with customer demand volatility,supply complexity and Raw material scarcity. In order to cope with that further concern in SCM needed during implementing VSM study.

The Unintended Consequences Unveiled

As organizations begin to implement Value Stream Mapping symbols, they often discover that the journey is not as straightforward as it seems. Unintended consequences can disrupt the very clarity that VSM promises to provide:

1. Symbol Overload

One of the earliest pitfalls is the temptation to overload your Value Stream Map with symbols. This stems from a desire to capture every detail of the process, but it can quickly lead to information overload. What was meant to simplify becomes cluttered, making it challenging to discern essential information.

2. Rigidity in Interpretation

While Value Stream Mapping symbols have standardized meanings, their interpretation can vary within an organization. Team members might perceive symbols differently, leading to misunderstandings and misaligned efforts. What was intended to bring clarity can turn into a source of confusion.

3. Blurring the Bigger Picture

Focusing excessively on symbols can cause teams to lose sight of the broader objectives of Value Stream Mapping. They become fixated on drawing perfect symbols rather than identifying and eliminating waste. The forest gets lost in the trees.

4. Resistance to Change

The introduction of Value Stream Mapping symbols can sometimes spark resistance among team members. They may perceive it as additional bureaucracy or a way to micromanage their work. This resistance can hinder the very improvements VSM aims to achieve.

5. Misplaced Priorities

In the pursuit of mapping processes with precision, organizations can lose sight of what truly matters. They may prioritize drawing aesthetically pleasing maps over implementing meaningful changes. The map becomes an end in itself rather than a means to an end.

6. Incomplete Mapping

Ironically, in the quest for detail, some organizations might neglect crucial parts of their value stream. They focus too much on certain areas while overlooking others, leaving gaps in their understanding.

Navigating Value Stream Mapping symbols Effectively

While VSM symbols can indeed introduce unintended consequences, they are not to blame. Instead, it’s how they are applied and interpreted that matters. Here are strategies to help you navigate the complexities and ensure your Value Stream Mapping leads to clarity rather than chaos:

1. Start with a Clear Purpose

Before diving into symbol-drawing mode, define your objectives clearly. Understand what you aim to achieve with your Value Stream Mapping exercise. Are you looking to reduce lead times, eliminate defects, or optimize resource allocation? Clarity of purpose guides the use of symbols.

2. Less is More

Resist the urge to overcomplicate your Value Stream Map with excessive symbols. Remember that the goal is to simplify complex processes. Focus on the critical few rather than the trivial many.

3. Standardize Interpretation

Establish clear guidelines for how symbols should be interpreted within your organization. Create a reference guide that team members can consult to ensure consistency in understanding.

4. Emphasize Communication

VSM is not a solo endeavor. Encourage open communication and collaboration among team members. Use the symbols as a means to facilitate discussions and problem-solving rather than as a rigid template.

5. Prioritize Action

Keep the bigger picture in mind. The ultimate goal of Value Stream Mapping is to drive improvements. Ensure that your VSM efforts result in actionable insights and changes.

6. Embrace Change Management

Recognize that introducing VSM may entail changes in workflow and processes. Implement change management practices to address resistance and ensure a smooth transition.

Conclusion: Balancing Clarity and Complexity

Value Stream Mapping symbols are powerful tools that can lead to enhanced clarity and efficiency when used effectively. However, like any tool, their impact depends on how they are wielded. The unintended consequences that organizations encounter often arise from misinterpretation, overemphasis, or misplaced priorities.

By approaching VSM with a clear purpose, standardizing interpretation, and emphasizing collaboration, organizations can maintain clarity while avoiding the chaos that can accompany symbol implementation. The path to successful Value Stream Mapping lies in striking a balance between simplicity and precision, using symbols as aids in the pursuit of continuous improvement.

So, don’t let the unintended consequences deter you. Embrace Value Stream Mapping symbols as valuable allies in your journey toward leaner, more efficient processes. When harnessed correctly, they can indeed lead you from clarity to greater clarity, bypassing the chaos along the way.

Read more VSM Blog post blow

Aji

Hi there welcome to leandemy.com, with decade of experience in lean and manufacturing I'd love to share ideas and know how to better understand of lean practice

Related Posts

Scientific Thinking: Navigating between fact in statistics and human psychological bias

Understanding How the Human Brain Shapes — and Sometimes Sabotages — Operational Problem Solving If you’ve worked in manufacturing long enough, you’ve probably faced it: the same downtime keeps reappearing, the same quality defect creeps back,...

Eight Disciplines Problem Solving : Navigating Bias trough structured framework

When the Brain Becomes the Hidden Defect and decline Company sales revenue There a lot of cases where in B2B business poor customer experience and Quality issue cause the sales decline. in a survey of 1,350...

Six Sigma vs AI: Future Talent Outlook in Continuous Improvement

Are You Lean practicioner within manufacturing industry? if yes you will notice that In all manufacturing sector the outlook of AI implemntation were growing According Research by Fortune bussiness insight , The global “AI in manufacturing”...

How to Make Hoshin Kanri X Matrix (Step-by-Step Guide)

How to Make Hoshin Kanri X Matrix (Step-by-Step Guide) Is your team great at hitting targets -- Just not the right one? Do your KPI's Change more often than your Machine changeovers? Ever feel like the...

Leader Standard Work Benefit: How to lead without falling for your own biases

Leader standard work benefit for manager is exercised to reduce your biases during decision making you will ask me how? when we think about a leader we often think about sharp mind, Quick instincts and Solid...

Kata coaching : Fostering lean culture trough scientific thinking

Introduction As managers, supervisors engineers or even analyst in profitable organization. we were fully understand that lean thinking and scientific thingking are oraganization must have culture. Why? Because without those, the company will facing difficult...

Please login to join discussion

ADVERTISEMENT