No products in the cart.

Kanban Definition, Element And key aspect for implementations

Kanban implementation best practice in operation & shopfloor management

Reading Time: 6 mins read

0

754

SHARES3.6k

VIEWSWhat is Kanban ?while it was currently a buzzword Information systems as well as the project management,

do you know where kanban is started?

It is started 80 years ago when The Kanban method was developed by Sakichi Toyoda Founder of Toyota.

The goal was to improve the flow of materials and enhance collaboration in the plant by creating visual signals. By the end of the 1940s, the Toyota plant had greatly reduced the time needed to make cars. It also had created one of the world’s first just-in-time production systems. The Kanban method was then applied to other manufacturing sectors and other types of businesses. It has since been adopted by the software development industry, as well as in marketing, IT, healthcare, and other fields.

read more to understand about kanban

What is Kanban?

Kanban is a Japanese word that means “visual signal”, In practical Kanban enabling visual management tools and in principle it reduces waste of inventory and waiting.

Managing operation can be daunting, operation manager spends their time 50% a day for meetings. While middle manager spends less, around 35% a day source: The muse. Other than KPI analysis, update the task progress are one of the most topics discussed during meetings. Let alone to analyze some problem solving it will be another extra hour.

To give more value-add time in the meeting and reduce time spent on project status, one of the notorious tools often used were Kanban. Kanban able to visualize operations status in one chart which is easy to digest. In this blog post, we’ll explain what Kanban is and how you can use it in operations or project management. as well as common pitfall when using the Kanban Tool.

Those two-factor made Kanban powerful tool used as best practice in many industries, including software development, information technology, operations and supply chain management. However not all Kanban program and implementation in manufacturing are smooth or always successful.

Kanban Board

The first Kanban system are the oldest it is the physical Kanban. When you need this Kanban tools? if you are managing rapid process which need update frequently in hourly basis with low budget then you are good with this type of Kanban. Physical Kanban are easy to made and good tools to provide insightful operation status for line leaders & supervisors. the easiest way to make this Kanban are illustrated below.

Those are physical Kanban you can implement in board however those based on task status of Preventive maintenance activity. How about developing kanban for production process? here some guide you can use to develop physical Kanban. first define the step process assure the process can be easily identified for example left to right and top to bottom.

Kanban Card

Kanban Shelf

Types of Kanban in manufacturing

Like any other Lean manufacturing tool, Kanban is not a silver bullet. It must be implemented correctly to be effective. You can implement Kanban in a number of ways matching your needs. depend on the first study case or problem you had you need to decide what kind of Kanban system to use. Mainly are three different Kanban systems. Which is digital Kanban, physical Kanban or mixed Kanban system (digital & physical).

Kanban benefit in manufacturing

In Lean manufacturing tools, Kanban is useful for improving stock and inventory. Since one of Muda or wastes are high inventory. To give your insight why inventory is sometimes overlooked? because of the push systems. In push system each work cell demanded to produce as their target however since the nature of the order are fluctuated it may generate huge amount of semi-finished goods or finished goods inventory. And inventory make company cashflow not so good.

Introductions Push to Pull systems

Kanban enables synergy to one work cell to another by generating signal how much the goods need to be produced. And by that principle reducing inventory and good cashflow will be following. Sounds nice & simple, isn’t it? However, you may ask does it can be happened. Yes, it is by reducing changeover time we can enhance flexibility and produce a goods in Order basis. And Thats called pull systems

Pull system example: Print on demand online T shirt

Kanban are powerful if implemented along with Single minutes exchange dies, Value stream mapping and Level scheduling or Heijunka. By doing so We can control inventory by order. Simple example of pull system is Print on demand Mug or T shirt. The print on demand market itself is expected to hit $10 billion by 2025. Rather than stocking already printed T-shirt, the business model depends on signal provided by the customer and print, and ship based on actual order. Averagely cost of each Custom shirt are below $10 with different Minimum order quality in several online platform.

Pull system example: Starbucks Coffee

Another example of pull system is when you ordered Starbucks coffee. They will make it right away based on your order and preferred size. For your information Starbucks invest in analysis to reduce wastes in the coffee creation process. By doing so they generate more customer engagement since they get the coffee faster.

Key parameter for Push & Pull System

If you already understand of pull system, the next questions are how we transform from push to pull system. We made simple table to visualize parameter need to be consider when you are analyzing does the transforming from push to pull are feasible or may not feasible. we consider the key element needed to define current process and next process and the wastes generated from inventory. By doing the Exercise you will grasp does the transformation from push to pull is relevant to your process or not relevant. Without further ado check the table below.

| Parameter | Type of parameter | Push system | Pull system |

| Process layout | Continuous line | X | |

| Not continuous line | X | ||

| Work in progress between process | Qty defined | X | |

| Qty not defined | X | ||

| Production batch size | One piece flow (not use batch) | X | |

| Huge batch size | X | ||

| Product size | Small lightweight product | X | |

| Huge heavy product | X | ||

| Product Mix | No / low product mix | X | |

| High product mix | X | ||

| Set up / changeover | Easy & not affect much in OEE | X | |

| Difficult and top los in OEE | X |

First, Kanban is a way of bringing simplicity to complex situations. It helps you understand your environment and streamline your operations.

Second, Kanban is a way of creating clarity. It promotes transparency and trust between teams throughout the organization by making the work visible.

Third, Kanban is a way of building momentum. It helps you transform your culture to one of continuous improvement. Fourth, Kanban is a way of creating human-centered systems. It takes into account the human factors that are often ignored in traditional management tools.

Conclusion

Kanban is a powerful tool for manufacturing businesses. It helps you make sure your processes are visualized, flowing at the right level, and optimized for efficiency. Kanban works well with other visual management tool, gemba walk and also Value stream mapping.

We hope this article has given you a better understanding of what Kanban is and how you can apply it in your business. Subcribe our post to increase value by understandinglean methodology.

Aji

Hi there welcome to leandemy.com, with decade of experience in lean and manufacturing I'd love to share ideas and know how to better understand of lean practice

Related Posts

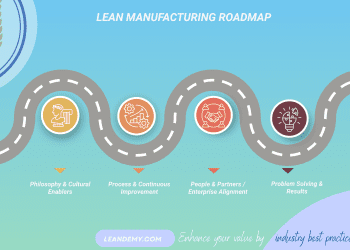

Lean Manufacturing Roadmap : Your Guide to Start the Transformation Journey

Introduction: Why You Need a Roadmap Before Starting Lean If you’ve been working in manufacturing, you’ve probably heard the buzz about “Lean Manufacturing.” It’s not just a trend — it’s a philosophy that helps...

A3 Problem Solving Ultimate Guide : Decoding Rootcause with 7 step 7 tools

A3 problem-solving Templates are one of lean manufacturing tools. It has practical ways to un woven complex issues. In the complex world of business operations, problems are inevitable. Whether they are small hiccups or significant hurdles,...

Hoshin Kanri : Translating Your Business Strategy into Roadmap

How Hoshin Kanri Can Steer Your Business Strategy Are you : Feeling lost at sea with your business goals? Staring at a strategic plan that feels disconnected from daily operations? If so, then Hoshin Kanri might...

Visual Management in the Operation : The Navigating Clarity in dynamic workplace

Visual management is the game-changer you didn't know your workplace needed! Imagine a world where everyone's on the same page, errors are minimized, and communication flows seamlessly—that's the power of visual management. In simple terms, visual...

A Comprehensive Guide to Total Productive Maintenance

In today's fast-paced industrial landscape, maximizing productivity while minimizing downtime is crucial for success. One approach gaining traction is Total Productive Maintenance (TPM), a proactive maintenance strategy aimed at optimizing equipment effectiveness. Recent studies converge...

Kaizen: The Power of Shifting Mindset & Domino effect towards efficiency

Kaizen often mentioned methodologies which leverage the bussiness. In the dynamic landscape of manufacturing, businesses are constantly seeking ways to enhance efficiency, productivity, and overall performance. One approach that has gained significant traction in recent years...

Please login to join discussion

ADVERTISEMENT