No products in the cart.

Kanban Card : three things you should know & example Template

Kanban Card ultimate guide Example, Template as well as tips to avoid pitfalls

Reading Time: 4 mins read

0

753

SHARES3.6k

VIEWSKanban card is a key enabler to shift from push system to pull system why? here the thing

One piece flow is a key principle that guides you lowering your inventory level. However, implementations are difficult to make one piece flow. One of them is due to machine limitations for changeover, minimum produced units or even transferring part between process. subject to process or we call it batch.

Kanban cards can be set to lowest minimum amount thus enabling us to implement pull systems. However many people not aware how to set out Kanban card.

read our article below to find out

Kanban Card key to implement pull system

Kanban card are component of Kanban system which contain information regarding how much exact quantity of production unit also what are the latest status. those informations was crucial since 45% f mnufactruing cost related with material. It means if you improving inventories and material efficiency company will be in good conditions in terms of financials.

The pull system basicallly benefitting the productions since only needed materialwere supplied. if you are operations manager, process engineer or supervisor in production. You may aware those ideal state cannnot be happens sincee the machine or processes has certain amount of allowable batch to operate.

Some teqnique of implementing pull system is to reduce the batch production ste by step. By doing so we can reduce inventory work in progess step by step. oher things that can be impprove from kanban implementaions were days of inventory.

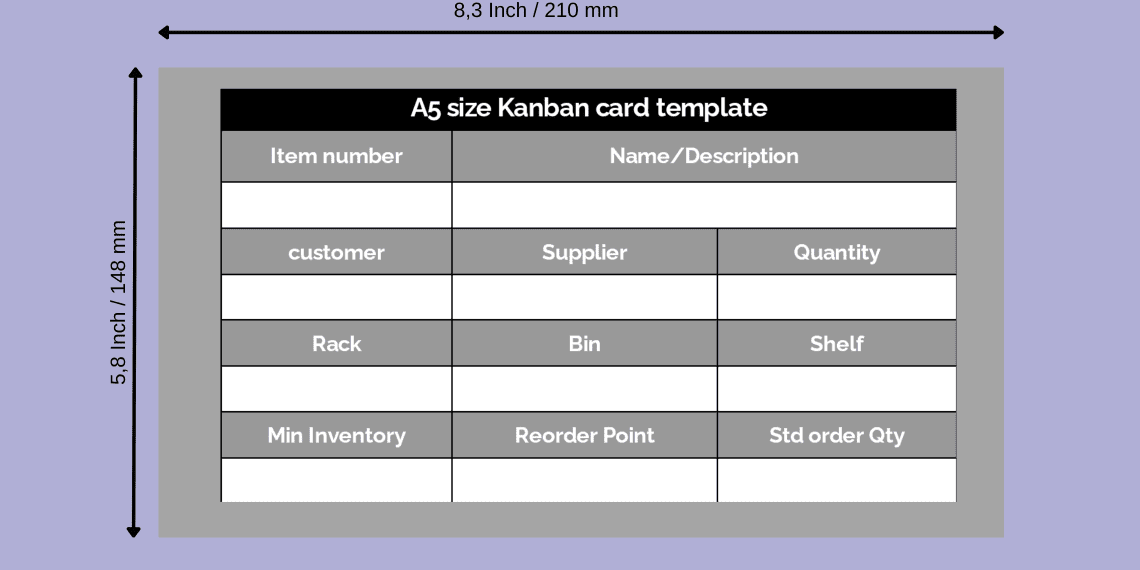

Kanban Card : Size & orientation Template

A5 kanban card

There are Several Size of Kanban card Template, ranged from A4 to A5. The Templates also has few Orientation from Horizontal to landscape template. However Considering the practicality A5 with landscape template are more Common Used In Industrial application.

Kanban card templates sized in A5 paper which contain parts identification number, detail on customer/Quantity, how much parts or material needed by the next process. In early days all data put using writings manual or even stamp. But those practice may cause error due to data writing were missed or incorrect description number.

Kanban card Flow, E2E (end to end)

Many of you might be wondering how is Kanban flow from beginning of process to end of supply. On manufacturing process there are 2 data flow which is information flow and the productions flow. information flow came from sales to Planner which usually in monthly basis.

Kanban card formations flow starts from finished goods ( downstream process ) to Upstream process ( raw material) while production flows from upstream process ( raw material) to downstream process ( finished Goods).

Kanban Flow

From picture above the orange arrow represent Information Flow. While purple arrow represent physicals goods flow. The Kanban card are representing the parts & information movement. By having Kanban card we able to had visibility both of information and the physical goods.

40% of manufacturing industry cost are on raw materials, however many in efficiency on raw material usage whether it is scrap, Defect or aging stock. Raw material efficiency are key important aspect of the plant performance. Kanban Card help to enable pull system thus avoid any over productions and material Wait in process.

Manual vs Digital Kanban Card

Recently some details are stored in qr code or bar code format which enable rapid process of reading Kanban cars also used as poka-yoke tools (error proof) system. Kanban card become one of tools that enable digitalization in industry 4.0 for assembly process as well as inventory management systems.

Example Kanban card : Sauce Bottle Packaging Process

To give you good picture lets take example on sauce bottle manufacturing production process. In sauce bottle 500 mL process there are three main machineries which is loading conveyor, filling and labelling the last is packaging. On the loading and filling are using Machine, while packaging were operated by manpower.

Due to Quality inspection the bottle need to wait 1 Ship to sample test before move to packaging. Thus needed to check the Status per shift. Based on this we need to define the Kanban card.

Kanban Example

Kanban card improvement metrics

Before define your Kanban card improvement matrix you need to know end to end process on how the planner and production works. In manufacturing production there are specifics meetings alignment between sales-Planner and production called SNOP

SNOP meetings consist of alignment on which product need to produce also resource the manufacturing had for example the raw material availability, machine utilizations and many more. Based on this meeting the planner will give production details on what are the production mix looks like, The target quantity, Shift planning as well as MP resource.

After SNOP phasing production are sent to production to execute. During day in the life there many things abnormality happens in manufacturing. Those abnormality may cause loose track of latest status and visibility of production progress. Kanban are good tools to see the productions status as well as the resource availability.

Conclusions

Kanban Card are good tools to improve raw material management by enabling pull system. However the implementation need to assure the key point inside the Kanban Card. For example :

a. How many pieces needed to produced

b. minimum inventory , reorder point

c. Emphasis the actual physical goods with the information’s in prompt manner

Aji

Hi there welcome to leandemy.com, with decade of experience in lean and manufacturing I'd love to share ideas and know how to better understand of lean practice

Related Posts

5S Audit Scorecards: Leveraging Insights From Assessment to Action

5S audit scorecards serve as vital tools in the pursuit of organizational excellence and efficiency. Stemming from Japanese manufacturing principles, the 5S lean methodology champions Sort, Set in order, Shine, Standardize, and Sustain principles. These pillars...

Value Stream Mapping symbols : From Clarity to Chaos The Unintended consequences

Value Stream Mapping symbols those iconic shapes and lines, play a crucial role in the VSM methodology. Which are considered a lean prestige tools and widely over promoted. Not many people are aware of unintended consequences...

Value Stream Map Example : Case study vital metrics you need to know before starting VSM

Value Stream Map example is one of key discussions in academic and lean practicioners. As one of wide known lean manufacturing tools, it is attracting many people. Allured by benefit of reduce wastes and streamline raw...

How to plan 5s Audit [Bonus! 5s audit checklist Free template]

5S audit are essentials program in lean manufacturing Tools. Tied with gemba walk It's widely known as basic tools to enhance the lean culture and productivity. Many mistakes are bound to happens since the 5s buzz words...

How to do effective Gemba walk in 5 step

Effective Gemba walk, are key aspect to build lean cultural transformations, Researcher said. However, in the long run Gemba walk effectiveness are being hard to sustain. The key were the top leader are harder to commit in...

Lean Manufacturing Principle : Decoding Leadership Missconceptions

Lean manufacturing principle is a topic which increased researcher attention along the year. Based on what we found at Academia.edu the word "lean manufacturing principles" there are 313.799 Papers with increased growth year by year. Lean...

Please login to join discussion

ADVERTISEMENT