No products in the cart.

Lean History timeline Updated [2024]

Reading Time: 5 mins read

0

805

SHARES3.8k

VIEWSWhat is lean Manufacturing?

What is lean manufacturing? how lean history changes the global economy?

it is a philosophy that implement in manufacturing industry to gain more by less. Lean method seeks more benefit by eliminate wastes rather than charge more money to customer. The term “lean” is taken from the Japanese words for “lean” and “to flow” and is used to describe the process of removing waste from production, which ensures that products are delivered on time with the highest quality possible.

the article wrote by James Womack in 1994 shock the world. His article from lean production to lean enterprise, it gives more spice for the industrialist to understand that there are new ways to play the game.

As strategy & system to enhance profitability, lean methodologies not formulated instantly. rather than invention and reapplication of best practice across industry in the last century. Since the nature of lean methodologies trial & practice, lean methodologies evolve from time-to-time befitting industry trends across the history timeline. and until now it still evolving and integrating match in digital industry services such as e-commerce, Banking & logistics.

Lean history Early stages: Standardizations parts

The history record that lean methodologies are started at 1450 in Vencie, Italy for shipyard assembly using canal, however the first publication and thought about time study began in 1700’s for cannon interchangeable spare parts by French general Jean-Baptise Vaquette de Gribeauval led for standardization of cannons known as Gribeauval system.

The system accomplishments were that solid cast cannons were bored to precise tolerances, the standardization of bore also enabling accuracy without sacrificing the range. Imagine during this period of time standardization of detailed spare part are hard to find. Even the earlier firearms are custom made we need to replace or came back to the firearm artisan if there are spare part need to be replaced. later on, Honore le Blanc made standard for flint of firearm and this is the start of emerging lean production.

Lean history in Early 1900’s: Time & Motion studies

Later in 1898 by F.W Taylor. His study started because he is astounding how his operator works in different way for the same task. He also thinks that the output is one third of the optimum condition. His publication widely spread across academics about scientific management.

His time study later on followed by Frank and Lilian Gilbreth which is study motion of worker, later the time and motion study became integral part one of field in industrial engineering. Those concept interchangeable part and also time-motion study developed and implemented in ford factory in which henry ford installed assembly lines as finishing line of car factory. Those is early era for scientific management which gave birth to another lean tools which is quality management.

Lean history in 1931: The dawn of quality era [SPC & PDCA]

To increase their quality-of-service Bell telephones engineer Walter A. Shewhart implementing statistical control to increase voice transmission. Later on, he also implemented SPC diagram in the Bell telephone equipment manufacturer western electric company. On the factory he put memorandum which change the world, he pointed a graph that indicates variation and revolutionize quality management from sorting defected product into variation reductions.

Later on, W. Edwards Deming served as the editor of Shewhart’s book Statistical Method from the Viewpoint of Quality Control (1939), invited Shewhart to speak at the Graduate School of the U.S. Department of Agriculture and after that American society for quality developed in1945. in 1950’s Deming invited to Japan as introduction for quality management systems and after that he met The Japanese Union of Scientists and Engineers (JUSE) also Japanese industrialists of the likes of Akio Morita, the cofounder of Sony Corporations in July and August 1950, in Tokyo and at the Hakone Convention Center.

Lean history in 1950’s: Toyota Production system

On his lecture at Hakone Convention center Deming sharing insight that by reducing variation will reduce cost of defect and increase market share. A number of Japanese manufacturers applied his techniques widely and experienced heretofore unheard-of levels of quality and productivity. The improved quality combined with the lowered cost created new international demand for Japanese products. Not stop in there Japanese’s needs for economic recovery leads the Toyota leader have ideas how to implement supermarket system in united states at auto factory why? since at that time to produce one piece of spare parts need resource that really scarce and the ideas one piece flow as well as Just in time created.

Lean history in 1961’s: Quality control circle

Admired implementation of Toyota Quality circle application Deming praised Toyota as an example of the practice QCC at early 1950’s later on leader of JUSE formalized the QCC at across Japan in 1961 and expanded by others, such as Kaoru Ishikawa founder of Ishikawa diagram. The program begun to spread across Japanese industry.

Lean history in 1985’s: Single minutes exchange dies

On a trip to the US in 1955, Taiichi Ohno observed Danly stamping presses with rapid die change capability. Subsequently, Toyota bought multiple Danly presses for the Motomachi plant. And Toyota started to work on improving the changeover time of their presses. They developed a structured approach based on a framework from the US World War II, Training within Industry (TWI) program, called ECRS – Eliminate, Combine, Rearrange, and Simplify. Over time they reduced these changeover times from hours to fifteen minutes by the 1960s, three minutes by the 1970s and then just 180 seconds by 1990s. THE SMED method widely spread aroung 1985 by Shigeo Shingo.

Lean history in 1988’s: Total productive maintenance

Total Productive Maintenance (TPM) was developed by Seiichi Nakajima in Japan between 1950 and 1970. One of the first companies to gain from this was Nippondenso, a company that created parts for Toyota.[1] They became the first winner of the PM prize. An internationally accepted TPM benchmark developed by the JIPM Seiichi Nakajima is therefore regarded as the father of TPM.[2]

The classic TPM process he developed consisting of 5 principles was later enhanced by the JIPM to incorporate many of the lessons of Lean Manufacturing and is referred to as Company-Wide TPM which consists of 8 principles/pillars.

Today era

In today era lean become implemented in information technology. For example, Andon in amazon when there is product not good, the system while take down those products from the web until it resolved.

Lean also emerges in other form such as Lean startup by eric reis. Where he found correlation between being lean and also how to create product that really needs by the customer. On his book he coined it is as MPV minimum viable product which is currently used as best practice in digital start-up company. In the last 300 years lean methodology and lean production are moving along with industry needs.

Conclusion:

Based on 300 years of industry trends, is proven that lean historically not faded. but even lean manufacturing strategy evolve to match industry needs more efficiently.

Aji

Hi there welcome to leandemy.com, with decade of experience in lean and manufacturing I'd love to share ideas and know how to better understand of lean practice

Related Posts

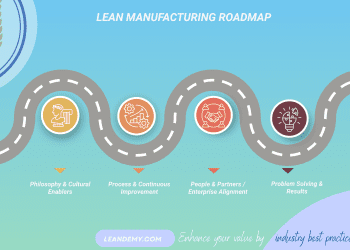

Lean Manufacturing Roadmap : Your Guide to Start the Transformation Journey

Introduction: Why You Need a Roadmap Before Starting Lean If you’ve been working in manufacturing, you’ve probably heard the buzz about “Lean Manufacturing.” It’s not just a trend — it’s a philosophy that helps...

A3 Problem Solving Ultimate Guide : Decoding Rootcause with 7 step 7 tools

A3 problem-solving Templates are one of lean manufacturing tools. It has practical ways to un woven complex issues. In the complex world of business operations, problems are inevitable. Whether they are small hiccups or significant hurdles,...

Hoshin Kanri : Translating Your Business Strategy into Roadmap

How Hoshin Kanri Can Steer Your Business Strategy Are you : Feeling lost at sea with your business goals? Staring at a strategic plan that feels disconnected from daily operations? If so, then Hoshin Kanri might...

Visual Management in the Operation : The Navigating Clarity in dynamic workplace

Visual management is the game-changer you didn't know your workplace needed! Imagine a world where everyone's on the same page, errors are minimized, and communication flows seamlessly—that's the power of visual management. In simple terms, visual...

A Comprehensive Guide to Total Productive Maintenance

In today's fast-paced industrial landscape, maximizing productivity while minimizing downtime is crucial for success. One approach gaining traction is Total Productive Maintenance (TPM), a proactive maintenance strategy aimed at optimizing equipment effectiveness. Recent studies converge...

Kaizen: The Power of Shifting Mindset & Domino effect towards efficiency

Kaizen often mentioned methodologies which leverage the bussiness. In the dynamic landscape of manufacturing, businesses are constantly seeking ways to enhance efficiency, productivity, and overall performance. One approach that has gained significant traction in recent years...

Please login to join discussion

ADVERTISEMENT